04/14/2021 Today it is difficult to imagine restorative dentistry without computer programs. Manual production of dentures by casting is gradually giving way to new, accurate and fast CAD/CAM technology in dentistry.

CAD/CAM is a modern digital technique that automates the process of creating dentures: the workpiece is modeled in an electronic program and milled on a computer numerical control (CNC) machine. The technology is applicable to zirconium, titanium, cobalt-chrome, glass ceramics, etc.

What are CAD and CAM?

- CAD – Computer-Aided Design (from English computer assistance in design and modeling). After scanning the oral cavity, the model is created in virtual space using special software. As a result, the crown fits perfectly.

- CAM – Computer-Aided Manufacturing (from English computer assistance in production). Data about the modeled product is transferred to a CNC machine, where the crown is automatically turned.

With traditional cast crowns, the patient experienced discomfort when making impressions, and situations could arise where the crown did not fit exactly. In addition, the production time of the prosthesis took an average of 2-3 days, during which the patient was left with exposed, ground teeth.

Not only are cad/cam crowns more accurate and superior than their casting sisters, but they are also produced significantly faster—reducing the number of dental visits to just one. At the same time, the patient can personally observe the production of the prosthesis, and it looks impressive.

Benefits of CAD/CAM

- Creation of structures of any shape and complexity.

- No discomfort when scanning the oral cavity.

- Speedy production of orthopedic structures.

- Ability to create products from different metals, including zirconium dioxide.

- High-precision computer technology (accuracy up to 25 microns).

CAD/CAM technology is suitable for creating one-piece ceramic and metal fixed prostheses of various types: crowns, veneers, abutments, etc. This method does not have the usual disadvantages of previous technologies: shrinkage, deformation, overheating of the metal, the presence of pores and unshed areas.

Stages of creating dentures

- Preparation for prosthetics (hygiene, sanitation, preparation of supporting teeth).

- Scanning the oral cavity with an intraoral scanner.

- Electronic three-dimensional modeling of an individual Ked/Kam crown.

- Automatic turning on a milling machine.

- Sintering and grinding.

What cad/cam programs are there?

For full operation of CAD/CAM equipment, correct software is required. The general name for software products that allow three-dimensional modeling and transfer of data to equipment is CAE. CAE – Computer Aided Engineering (from English computer assistance in engineering analysis). Essentially, this system controls the operation of equipment, analyzes and automates numerical calculations.

A separate CAD/CAM program is compatible with open-type design systems in which components (scanner, software, milling machine, consumables, etc.) can be replaced. In closed systems, software modules are already integrated into the database.

Popular Digital Dentistry Software:

- Exocad Dentalcad.

Exocad is a completely open program that is compatible with almost any hardware. It features high processing speed, flexible settings and ease of use. Exocad already offers a wide range of capabilities in its basic version, and additional modules make it a powerful professional tool. - Dental System.

This software is constantly updated and the main modeling tools are improved. Today Dental System allows you to combine equipment, materials and all the achievements of digital dentistry to obtain maximum results.

Planmeca.

Planmeca is the leading visualization software, supporting the widest range of 2D and 3D methods. The open system is compatible with any equipment, convenient and easy to manage.

These are not all CAD/CAM programs available on the market for digital dentistry solutions. Their capabilities are constantly being improved, expanding the scope of use, methods and list of materials. And we can confidently say that with the development of CAD/CAM, a new era in dentistry has begun!

Advantages of the CAD/CAM system compared to the “classical” production of structures.

The undeniable advantages of the system include:

- High precision in product manufacturing - no shrinkage or deformation of the material, ensuring the highest quality finished product that fully complies with the specified parameters;

- The ability to take into account the needs of any patient - The ability to manufacture objects of any complexity and configuration, including hollow ones;

- Possibility of manufacturing prostheses from zirconium dioxide;

- Minimum production time for dental structures - visualization of intermediate and final results, their agreement with the patient allows you to start the manufacturing process in the shortest possible time;

- Fully automated manufacturing process, eliminating the human factor;

- Compact installation dimensions.

Brief economic calculation of a 3D metal printer for dentistry:

1. The cost of the powder (25-40 microns) is 18,000 rubles. Cost (direct) of manufacturing 1 frame (2g product + 1g support) = 3*18=54 rubles. 2. Production time for 60 units – 2 hours. The number of loads per day is 4. The number of manufactured units per day is 240. 3. When one machine is filled to 60% with LSP (240*22*0.6), the total number of units will be 3168 (taking into account defects and rework). 4. With the cost of laser sintering on the market starting from 300 rubles, the gross profit will be 728,000 rubles. 5. The payback of the technology at 60% load will be less than 10 months.

Orthopedic structures manufactured using CAD/CAM technology

CAD/CAM technology makes it possible to produce removable and fixed models of prostheses, as well as products of other types, in particular, surgical templates. However, despite the presented functionality, CAD/CAM is most widely used to create permanent orthopedic models:

- veneers;

- tabs;

- crowns made of solid ceramics and zirconium;

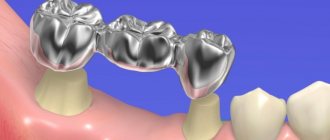

- bridge structures;

- telescopic crowns;

- temporary crowns that require production in the shortest possible time.

- individual abutments for implantation.

Advantages and disadvantages of the system

Any technology for manufacturing dentures has both its pros and cons. The CAD/CAM system in dentistry is no exception, although, of course, it has more positive aspects.

Advantages of prostheses made using this technology:

- They have exceptional accuracy. The usual technique involves taking impressions by a prosthodontist, casting a jaw model from plaster by a dental technician, hand-making the frame and coating it with ceramics. During all these stages, minor errors inevitably occur (independent of the qualifications of specialists), which together lead to inaccuracy of the finished prosthesis and possible discomfort when wearing it. The CAD/CAM system reduces to zero the likelihood of error and inconvenience of the future design.

- They do not cause discomfort, do not rub the gums, and do not cause pain. They are characterized by high strength and durability, as the exceptional strength does not cause premature overload of the prosthesis and reduces the likelihood of breakage.

- The manufacturing time of a structure using computer technology is significantly less than using the classical method. On average, the patient receives a finished design in a few hours, while the usual process of creating dentures, using impressions and the work of a dental technician, lasts about 5-7 days. Therefore, the CAD/CAM system is indispensable in emergency cases when it is necessary to urgently restore the dentition (for example, before an important event).

- The patient can see his future prosthesis on the computer screen in advance, if necessary, discuss possible options with the dentist and adjust the final result. This significantly increases the aesthetic satisfaction of both the patient from the prosthesis received and the doctor from the quality work done.

- CAD/CAM technology in dentistry allows us to help people even with the most difficult clinical cases. For example, the need to prepare a large number of teeth in case of malocclusion makes it difficult to manufacture a prosthesis according to the classical version, since there is a high probability of a strong error. But computer scanning will allow you to accurately calculate the angle of inclination of each tooth and program the ideal design for each case.

- CAD/CAM technologies make it possible to produce a prosthesis from any type of material - alloys of cobalt and chromium, zirconium dioxide, ceramics, composite material. The computer has several programs to work with each of these substances to produce a highly aesthetic final product.

The only significant disadvantage of prostheses made using the CAD/CAM system is their high cost. The use of computer equipment for prosthetics increases the price by an average of 2.5–3 times.

What is the technology

The main advantage of the CAD/CAM system in dentistry is that the types of prostheses produced are highly accurate compared to conventional prosthetics. The use of a computer also ensures the speed of production and high convenience of the product for the patient.

This technique requires the following tools:

- intraoral camera;

- directly the computer;

- milling machine.

After selecting the required elements, you can proceed to creating prostheses, which includes several stages:

- An orthopedic dentist prepares teeth for prosthetics. Using a drill, he grinds off some of the enamel and dentin from the tooth - this is necessary to create space for the future prosthesis. This stage is no different from conventional orthopedic preparation.

- The doctor takes a virtual impression of the patient’s teeth using an intraoral camera. Its use has a huge advantage for prosthetics for people with an increased gag reflex, for whom taking conventional impressions with impression material on trays is a difficult and sometimes insoluble test.

- At the end of the appointment, the prepared teeth are covered with protective varnish or artificial crowns. This is done to prevent pain and increased sensitivity.

Taking an impression

The further process of creating a prosthesis occurs without the participation of the patient and is carried out on a computer or laptop on which the CAD/CAM program is installed:

- Information from the intraoral camera is transferred to computer media.

- Using a special program, the doctor creates a virtual three-dimensional sketch of the future prosthesis. The patient’s teeth, located symmetrically on the other side of the jaw, serve as a standard for the simulated teeth. If there are none, the program itself selects the optimal result. The advantage is that you can select several different options (shape, inclination of teeth), adjust and discuss them with the patient. The duration of this stage can vary from several minutes to 1-2 hours, depending on the complexity of the initial situation.

- After determining the final version, its 3D sketch is saved. The information is sent to the milling machine on which the frame is manufactured. The material can be cobalt-chromium alloy or zirconium dioxide. The metal block is processed with special cutters in the sequence specified by the computer, and the frame of the future prosthesis is obtained. Then it is ground and polished. The turning process lasts approximately 10-15 minutes.

- To increase the aesthetic effect, the metal part is coated with ceramic mass in a special oven.

- The finished prosthesis is transferred to the dental office and tried on by the patient. After fitting, the artificial teeth are fixed to the jaw.

Control systems programming training program:

| MODULE 1. G and M codes |

| Basics of programming CNC machines. |

| Basic G and M codes. CIMCO Edit |

| MODULE 2. CAD |

| Familiarization with the menu of CAD programs. |

| Sketch construction |

| Construction of body parts |

| Construction of rotation parts |

| MODULE 4. CAM |

| Familiarization with the CAM program menu |

| Importing parts into CAM. Creating a blank primitive. |

| Setting the workpiece to “0” |

| Creating a turning/milling operation. Exploring the Processing Operations Menu |

SUBMIT YOUR APPLICATION