What is this?

A bridge is a structure that consists of an artificial tooth (several) located between two crowns.

Crowns perform an important missing function and are placed on abutment teeth adjacent to the missing tooth. Such bridges are fixed using crowns, special glue and inlays, sleeves with pins. Several technologies are used in this complex process. As the name suggests, metal sleeves are used for manufacturing, from which single crowns are created; at the next stage, when soldered, they become a single whole structure.

The use of bridges is prescribed to replace missing natural teeth with artificial ones. It is used in the absence of one or several teeth in a row in a row.

Indications for installation

Like any denture, a “bridge” helps restore the aesthetics of a smile, eliminate speech defects and redistribute the chewing load in the dentition. It is an alternative to direct implantation, but is not suitable for all patients. Main indications:

- loss of 1 tooth (if there are contraindications to installing an implant);

- loss of more than 1 tooth in a row;

- replacement of a previously installed bridge prosthesis.

Installation of such a structure is contraindicated in the absence of a large number of teeth (more than 4 in a row), diseases of bone tissue (osteoporosis, osteomyelitis), chronic periodontal disease, acute inflammatory processes in the oral cavity, and malocclusion pathologies.

Advantages and disadvantages:

+ small wall thickness, and this, first of all, indicates that at the preparatory stage it will be necessary to clean a small amount of dental tissue. Accordingly, the cost, based on this, will be low.

— the main disadvantage is the lack of precision in the fit of the crowns to the teeth, due to the manufacturing features. As a result, caries develops underneath them, which subsequently leads to complete destruction. It is not uncommon for a bridge to injure the gums, leading to chronic inflammation of the gums. In the future, inflammation can lead to periodontal disease and tooth loss.

- not only a plus, but also a minus is the small thickness of the walls. They quickly lose their function due to chewing loads, wear out and break.

— the solder of the product contains metals (copper, zinc, cadmium, bismuth), which, in turn, cause adverse reactions in the body: irritation of the oral cavity, affecting the oral mucosa, provokes a disease of the digestive system and severe discomfort.

- due to the influence of saliva, metals oxidize, and an unpleasant taste appears in the person’s mouth.

— the strength of soldered products is much lower than that of solid cast structures.

— crowns have poor relief of the chewing surface due to their unevenness. These deficiencies interfere with the grinding of food and lead to problems with the mandibular joints.

Types of structures:

- Metal-ceramic.

- Adhesive.

- Solid cast.

- Stamped.

- Ceramic.

- Bridge-like structure with submerged supports.

Indications and contraindications

Orthopedic structures using the soldering method are rarely used today. But their installation is justified in the following situations:

- restoration is carried out with the elimination of medium and small defects;

- prosthetics are performed for the chewing group or incisors, with the fangs acting as a support;

- the supporting units are stable and can withstand the load of the bridge structure.

Contraindications include:

- the end elements have defects;

- three or more adjacent teeth are missing;

- there is a high degree of mobility;

- the coronal part is severely destroyed;

- enamel wear is pathological;

- there are malocclusions;

- some forms of periodontitis.

Solid bridge

The product is made using special casting. The advantage is that the crown itself fits firmly to the ground tooth, so the places in contact with the gum and possible gaps are not clogged with food debris.

This type completely eliminates destruction. There are also disadvantages to this design. This is primarily a great sensitivity to hot. A person experiences discomfort when eating hot food.

General overview

Soldered prostheses are orthopedic all-metal fixed structures.

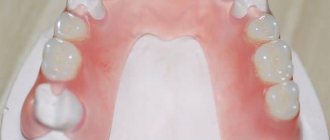

They consist of stamped caps (crowns) and a hanging block of cast artificial teeth, joined together by soldering. They resemble a bridge made up of two supports and a suspension element. Due to their unique design features, dentists call the structures bridges or bridges.

The stamped cap is a supporting element. It fits over the existing tooth and serves to firmly secure the bridge in your mouth. Between the crowns, which perform a supporting function, there is a “suspension” element necessary to replace the defect in the dentition and restore adequate chewing function.

Orthopedists prefer an all-metal structure, however, if the frontal region needs to be restored, where aesthetics are important, the front surface of the prosthesis is lined with plastic.

Soldered bridges have many disadvantages, but due to their low cost and speed of production, they are still popular with patients.

Pros and cons of the design

The positive aspects of these prostheses include:

- Small wall thickness , which requires the removal of only a small amount of dental tissue during preparation.

- Low cost.

The disadvantages of these designs are much greater than the advantages:

- Due to the peculiarities of creating the prosthesis, there is no precise fit to the supporting teeth. The consequence of this deficiency is the development of caries, leading to rapid destruction.

Also, an inaccurate fit can cause injury to the gum tissue with subsequent development of inflammation. - Rapid erasure of the crown walls due to their small thickness. This fact also leads to loss of functionality of the prosthesis and breakdowns.

- The metals contained in solder often provoke adverse reactions from the body - redness and irritation of the tissues of the oral cavity, digestive disorders, and severe discomfort.

- The appearance of an unpleasant taste in the mouth and bleeding gums due to oxidation of the metal by saliva.

- The strength of soldered structures is inferior to the strength of solid cast ones.

- The crowns have an unclear relief of the chewing surface , which leads to impaired chewing of food and problems with the mandibular joint.

- Rapid darkening of the soldering line , which worsens the overall aesthetics of the smile (especially if the anterior group of teeth was restored).

- The occurrence of a complication – galvanism, i.e. metal intolerance in the form of allergies.

Important: a large number of disadvantages led to a sharp decrease in patients’ demand for the installation of soldered prostheses.

In the video, the doctor talks in more detail about the pros and cons of bridges.

Indications and contraindications

The installation of soldered bridges is indicated when restoring your own lost teeth with artificial structures. They are used if no more than 4 teeth in a row are missing in one of the rows.

In addition, the model in question can be placed for the following indications:

- various damage to the crown parts of natural teeth;

- anomalies of shape and unnatural position;

- treatment of enamel coating abrasion;

- pathological occlusion;

- disturbances in the functioning of the masticatory muscle group;

- small teeth.

It is not recommended to use this technique in the following conditions:

- defects that disrupt the orientation function of periodontal tissue fibers;

- chronic diseases caused by viral infection (for example, tuberculosis);

- allergies to the alloys used;

- extensive defects;

- deep traumatic occlusion;

- pathologies associated with high mobility of dental units in the presence of a low crown part, weakened periodontium;

- inflammatory diseases (gingivitis, periodontitis);

- bruxism;

- serious pathologies in which the condition and quality of bone tissue changes (for example, with osteomyelitis or osteoporosis);

- psychoneurology;

- blood diseases;

- chronic form of certain somatic diseases that are in the acute stage;

- poor oral hygiene.

Important: many of the listed contraindications can be considered relative. Their elimination makes prosthetics possible.

Bridge stamped and soldered

This method is considered the oldest and has been used since Soviet times. Made from a thin-walled sleeve shell. This occurs during the process of compressing a plaster copy of the tooth. At the joints they are soldered, which ensures a continuous connecting structure.

Disadvantages can be considered:

- the impossibility of creating an exact shape due to a loose fit,

- using this type of prosthetics, there is a high probability that caries will form in the future and this will lead to tooth loss,

- the walls turn out to be thin and, as a result, quickly wear off, which leads to destruction and breakage.

- Patients experience bleeding from the gums and an unpleasant metallic taste due to metal oxidation.

Manufacturing

The devices are made by compressing a sleeve with thin metal walls into a copy of the desired tooth from a hard material. The crowns are connected to each other using soldering, which makes the connection continuous. But the stamping method does not allow the tooth to be recreated with high accuracy, which is why the prosthesis does not fit tightly.

A crown resembles a cap that fits over a tooth, with cusps. The upper part of the dentures should resemble the natural chewing surface as much as possible so that the patient can eat comfortably. But due to low precision during stamping, this is not always achieved.

Bridged Maryland

In prosthetics, this design is used with submerged supports. It differs from the classic type in that not complete, but partial turning is carried out in the places selected for supports; small cavities are made there for immersing the legs of the prosthesis into them. Subsequently, the cavities are closed with fillings.

Advantages and disadvantages:

- The main positive quality of this type is considered to be preservation of the pulp and minor removal of enamel. Therefore, gum disease is excluded in this case.

- This type of prosthetics is used only if the supporting teeth are healthy.

- The prosthesis is considered ideal only for temporary restoration.

- The product itself is not durable, since the legs cannot withstand heavy loads and can become cemented.

- In modern practice, the Maryland method is used only in the front rows.

What material is used?

The stamped-soldered bridge product is made from metal alloys of noble (palladium, silver, gold) and base metals (chrome, stainless steel, nickel). For cladding, elements of acrylic plastics are used.

Indications for manufacture and use:

- various damages,

- developmental anomalies of position and shape,

- clasp support arms are incorrectly positioned,

- special support for bridges,

- treatment of tooth abrasion,

- pathological occlusions,

- dysfunction of the masticatory muscles,

- incorrect bite development,

- not large sizes of teeth. Subsequently, the cavities are closed with fillings.

Contraindications for use are:

- Defects that disrupt the orientation function of periodontal fibers.

- Defects that are associated with high mobility in the presence of a small clinical crown with a small reserve of periodontal strength. This happens with short roots.

- Diseases associated with viral infection. These are chronic diseases, such as tuberculosis, as well as a period of chronic exacerbations.

The process of preparing the dentition

Preparation begins with dental treatment and, if necessary, removal of nerves, including in the supporting teeth planned for installation. In case of severe destruction, special tabs are used to help withstand severe loads. If the indications are favorable, then the nerves are not removed.

Structure

The teeth in an orthodontic bridge are made of metal. The most commonly used are cobalt-chromium alloys. The design of this type of prosthesis implies the presence of at least 2 crowns, which serve as supporting elements.

Stamped-soldered bridges are a type of prosthetics in dentistry.

The design contains at least 2 crowns, between which an artificial tooth is located. Products are classified as chrome plated or titanium nitride coated.

If the patient experiences discomfort after installation, the deficiencies are corrected. High-quality care involves the use of home irrigators.

Between them is an artificial tooth. The prosthesis can be solid or have a lining made of composite materials or plastics (facet or insoma). Structures of the second type have low strength, they require special control and periodic modification.

The reliability of titanium stamped-brazed bridges depends not only on the quality of the laboratory’s work, but also on the health of the patient’s supporting teeth.

Medical titanium does not leave a metallic taste in the mouth and does not oxidize.

Dentist

Novikova Olga Alexandrovna

8 years of experience

The chewing surfaces of dentures should follow the natural pattern of teeth as much as possible to achieve optimal occlusion. The buccal cusps below and the palatal cusps above are especially important. They compress food and are also responsible for distributing the chewing load along the vertical axis of the bone formation.

The buccal tubercles of the prosthesis above and the lingual tubercles below are responsible for separating food, ensuring clear articulation and protecting the surface of the cheeks and tongue. They are called "protective" because of their functions.

Production technology

The production of soldered bridge structures is a labor-intensive and complex process that consists of several clinical and laboratory procedures.

Therefore, to undergo this type of prosthetics, the patient needs to visit the clinic several times.

Taking impressions

Before taking impressions, a set of primary measures is carried out, the purpose of which is to ensure the functionality of the dentofacial apparatus and its future health.

It includes a comprehensive examination and therapy of the patient’s oral cavity in identifying diseases.

The following actions of the dentist are aimed at directly preparing the teeth for prosthetics. If there are indications, the supporting units are necessarily cured, and if necessary, the nerves are also removed .

After preparing the oral cavity, the supporting teeth are prepared (grinded). This manipulation provides conditions for reliable fixation of the crowns, and consists in removing a certain layer of dentin from the surfaces of these elements.

The preparation must take place under local anesthesia with simultaneous cooling of the treated area. The size of the removed tissue layer is always equal to the thickness of the walls of the artificial crown, which is 0.3 mm.

This is interesting: Which crowns to put and what to choose: metal ceramics or zirconium

During the process, the doctor makes sure that the walls undergoing the procedure are parallel.

At the end of all actions, an impression is taken. For this, a standard impression tray and alginate mass are used. Instead of alginate, you can use dental plaster, but due to the labor-intensive nature of the work, it is used in isolated cases.

Important: to improve the retention of the material, it is proposed to treat the edges of the impression tray with adhesive.

After the impression is removed from the oral cavity, it is checked and disinfected. If the patient develops sensitivity and mild pain on the prepared units, the exposed dentin is treated with a desensitizer.

While a permanent prosthesis is being manufactured, the doctor may recommend a temporary one, which will allow the jaws and tissues to get used to the changes. The temporary structure will also protect the treated surfaces from unwanted infection.

In addition, to prevent the occurrence of inflammation in periodontal tissues, regenerative and anti-inflammatory therapy is prescribed.

Model making

In the laboratory, the technician begins his work by assessing the impression obtained. If the quality of the taken copy allows us to proceed to further production stages, he creates plaster models of the jaw.

Finished products are installed in the central ratio position. It is important to note that the intercuspal contact position of the teeth is individual for each patient.

Central occlusion is determined using special wax samples.

After determining the occlusion and central contact using plaster, the model is fixed in a special device, which was created to test the operation of artificial dental structures.

In dentistry, such a device is called an occluder. With its help, the technician can completely recreate the anatomical shape of the teeth and simulate the movements of the jaws in the open and closed position of the mouth.

Modeling the prosthesis body

After the gypsum mass has completely hardened, the model is rid of excess material that fixed it in the optimal position. Only the jaw model remains on the device.

Next, using wax, the stump of the prepared supporting elements is modeled, bringing its shape to the most natural appearance. The models remain fixed.

At the next laboratory stage, a technician cuts off the plaster with a special knife, making stamps.

Copies of cut dies are cast from metal alloys with a low melting point, which serve as the basis for stamping crowns that act as supports.

The finished products are transferred from the laboratory to the doctor for fitting in the patient’s oral cavity.

A crown intended for fixation on supporting units must meet a number of requirements, namely:

- ideally fit the natural shape of the bone organs;

- have a pronounced spherical surface that will protect the gums from food particles;

- the depth of immersion of the product under the gingival margin should be no more than 0.3 mm;

- overbite after installation should be excluded;

- ensure tight contact with the tooth surface and the area of the tooth neck;

- recreate the anatomical contact points of adjacent teeth.

If the crowns fully comply with the stated requirements and the doctor is satisfied with the design parameters, then he immediately makes impressions of them, which will serve as a model for modeling the body of the prosthesis.

Using the finished model, metal elements are cast from wax, which will subsequently replace the lost teeth. The crowns and impressions are again sent to the technician, who, following all the technical rules, will make the body of the prosthesis from wax.

Let's look at the steps of this procedure:

- the model is treated with water to prevent wax from sticking to it;

- the space between the supporting elements is covered with a wax roller, the volume and height of which exceeds the parameters of future new elements;

- The models of the upper and mobile jaws are fixed in the position of maximum intertubercular closure of the teeth;

- of the antagonist teeth is imprinted

- markings are placed on the roller , determining the number of intermediate teeth that form the body of the prosthesis;

- modeling of the chewing and vestibular surfaces of the restored elements is carried out.

The main stage of manufacturing the body of the structure is the formation of a prosthetic bed, which faces the gum tissue.

In order to avoid injuries to the surface of the tongue during the operation of the structure, the technician smoothes the transitions between the teeth on the oral side. Rounded bumps form on the chewing elements.

Casting

At the next stage, the wax model is redirected to the foundry. There, a metal product is cast on the basis of a wax sample.

Process algorithm:

- pins are installed in the wax product;

- a system of channels is created through which the molten metal will enter the casting mold;

- removing the wax composition from the model;

- creation of a casting tank;

- processing the wax composition with a facing layer;

- drying the coating;

- installation of a special metal form with a ward cone and a special additional element on the vibrator;

- pouring material for formation;

- release of the dental cuvette from the ward cone;

- removal of pins;

- wax melting;

- heat treatment of the mold;

- metal pouring;

- freeing the product from molding compounds;

- mechanical processing of the finished prosthesis body.

Soldering parts

After returning the finished pendant block from the foundry laboratory, it must somehow be connected to the stamped caps. This can be done:

- On a plaster model.

- Without using a model.

If the first method is practiced, the hanging block is glued to the supporting elements with wax. The structure is plastered into a ditch. In this case, the chewing surface should not be immersed in the refractory mixture.

When using the second method, the stamped caps are freed from the wax that fills them. To do this, the structure is heated over a burner flame.

The model must also be cleaned of wax. Surfaces that will be soldered are degreased and scale is removed. The bridge elements are installed on the model and fixed together with sticky wax.

Making sure that the adhesion is not broken, remove the prosthesis from the model. Next, plaster is applied in a refractory mass.

There is another modern soldering method using electric spot welding. It speeds up the technician’s work because... eliminates the plastering stage.

This is interesting: CAD system

The solder must have the following characteristics:

- The melting point is 50 - 100 °C lower than that of the base metal.

- Fluidity, to ensure high-quality fluxing.

- Diffuse to easily penetrate the structure of the base metal.

- Resistant to alkaline and acidic agents.

- Color that matches the base metal.

- Anti-corrosion.

- Physico-chemical properties close to the base metal.

- No shells or bubbles.

Finishing

After all production work has been carried out, the prosthesis is washed under cold water and the remains of auxiliary materials used during the formation of the entire structure are removed from its surface. Next, the product is bleached in a solution of hydrogen chloride.

Final finishing involves the use of a filing tool, artificial silicon carbide stones, and dental grinding discs.

With these devices, the specialist removes excess solder, smoothes out irregularities, processes the joints of elements and the occlusal surface of the crowns.

At the next stage of finishing, work is carried out aimed at polishing all components of the structure.

The final process is polishing. It is carried out using a special paste based on chromium oxide. After this manipulation has been performed well, the prosthesis is ready for installation.

Watch the video to see how bridges are installed.

Have you lost a tooth or a pair, or maybe more than one? What to do, how to get back what was lost

Each person is individual and each person has different attitudes towards the health of their teeth. For some, the loss of one tooth is already a personal tragedy, but for others, the absence of the entire chewing group of teeth is nothing, the main thing is that the “facade” (the frontal group of teeth visible when smiling) is intact. But in one case or another, sooner or later, a person who has lost one tooth or a group of teeth is faced with the question of how to regain what was lost, how to restore chewing function or restore the aesthetics of a smile.

Puzzled, a person goes to a dental clinic, where with such questions he gets a consultation with an orthopedic dentist and from him the person, who has already become a patient, learns that there is classical dental prosthetics using removable and non-removable orthopedic structures. And not so long ago, a type of prosthetics appeared, prosthetics on implants.

What is each type of prosthetics? This is what we will analyze in this article, so that if, God forbid, you ever have to face a similar problem, you will at least be a little oriented in this issue and better understand your dentist , with whom you will have to work closely to solve the problem that has arisen.

And so, non-removable orthopedic structures. These include crowns and bridges (in common parlance, bridges). Crowns are a kind of cap that covers the stump of a tooth. A tooth stump is a tooth processed or restored specifically for a crown, i.e. If the tooth is no longer there, then it will no longer be possible to restore it with a crown. Crowns come in different types depending on the manufacturing method and the material from which they are made: stamped steel crowns, solid steel crowns, ceramic crowns, metal-ceramic crowns, metal-free ceramic crowns, plastic crowns, metal-plastic crowns. Let's look at each type in more detail.

Plastic crowns. Made from acrylic plastic.

Advantages: low cost compared to other crowns, quick production, color (several shades of white). Disadvantages: low wear resistance. It is almost impossible to completely match the color to adjacent natural teeth. Over time, the color of plastic crowns may change (darkening). At our Denta Area clinic, we use plastic crowns exclusively as temporary structures for the duration of tooth treatment or while another more complex orthopedic structure is being made.

Stamped steel crowns. They are made from standard factory cobalt-chrome blanks (sleeves). Advantages: low cost in comparison with other crowns, more durable than plastic ones, minimal processing of hard tooth tissues due to the small thickness of the crown walls. Disadvantages: the small thickness of the crown (approximately 0.3 mm), due to this, the crowns wear out over time (a hole appears on the chewing surface), such crowns must be changed immediately. Inaccurate fit of the crown to the tooth stump (large gaps often remain between the tooth and the crown), as a result of which if the crown becomes short (a gap appears between the edge of the crown and the gum), then food debris accumulates under the crown, which leads to the destruction of the hard tissues of the tooth under the crown and the loss of this tooth. The anatomical shape of a natural tooth with its cusps and fissures (the depressions between the cusps) on such crowns is often not modeled at all or is modeled very conditionally, which negatively affects the process of chewing food. Although, of course, you can get used to everything, but is it worth getting used to? At our Denta Area clinic, we produce this type of crowns at the request of patients, but we always recommend considering other more functional types of orthopedic structures.

Solid steel crowns. Cast from cobalt-chrome alloy. The crown is pre-modeled from wax on the patient's model, which gives it individuality. Advantages: Precise fit of the crown to the tooth stump (the distance between the inner wall of the crown and the tooth is minimal), sufficient thickness from 0.5 to 1.0 mm, in some places up to 1.5 mm, due to which it is very wear-resistant, almost never rubbed (“eaten away” ). The anatomical shape of the tooth (tubercles, fissures) is well restored, due to which the chewing function of the tooth is well restored. Disadvantages: the cost is higher than that of stamped steel crowns. Not aesthetically pleasing, chromed steel or yellow (nitrite titanium coating). At our Denta Area clinic, we believe that this is the optimal type of crown for the chewing group of teeth if you want to save a little on ceramic restorations without losing the quality of restoration of chewing function.

Metal-ceramic crowns. They are made by applying and firing ceramic masses onto an individually cast metal frame (cap) made of cobalt-chrome alloy. Advantages: Aesthetics due to the wide range of colors of ceramic masses and the possibility of tinting with special paints. The color does not change over time. Functionality, well restore the anatomical shape of the tooth and chewing efficiency. The crown fits tightly to the stump of the tooth. Ceramic cladding is durable and almost never chips. Wear-resistant. They are used for prosthetics of any group of teeth (both anterior and lateral chewing). Disadvantages: Relatively high cost.

Metal-free ceramic crowns. Ceramic crowns on a frame made of zirconium dioxide or aluminum oxide. Advantages: the zirconium dioxide frame is white, in metal-ceramic structures the metal frame can give a gray tint, especially at the edge of the crown, where the ceramic layer is minimal, in metal-free structures this is excluded, the zirconium dioxide frame is light and durable, and when using metal-free structures the presence of metal in the oral cavity. They are used for prosthetics of any group of teeth (both anterior and lateral chewing). Disadvantage: High cost.

Ceramic crowns. They are frameless all-ceramic structures. Advantages: Highly aesthetic, as close as possible in appearance to natural teeth. Disadvantages: High cost, limited indications for use (only the frontal group of teeth).

Metal-plastic crowns. They are a metal frame made of chromium-cobalt alloy coated with plastic. Better than just plastic crowns, but worse than any ceramic structures in a number of indicators. Advantages: cheap alternative to metal ceramics. Disadvantages: Low aesthetics due to limited possibilities in choosing colors and shades, low wear resistance of plastic cladding.

Bridges are an orthopedic structure consisting of supporting crowns and an intermediate part that replaces missing teeth. Abutment crowns are placed on the teeth that limit the defect (the place where there used to be teeth, but now for some reason they are missing). The number of abutment crowns is variable and depends on the number of missing teeth and the health of the remaining ones. The intermediate part consists of artificial teeth, while between the artificial teeth and the gum there is a space, the so-called “washing space”, the width of the washing space also varies from very noticeable to barely noticeable, in some cases there is no such space at all. All these design nuances depend on the specific conditions in the patient’s oral cavity and the type of orthopedic structure. The types and names of bridge prostheses can be associated with the type of crowns they rest on, if they are solid crowns, then the bridge prosthesis is solid, if they are metal-ceramic, then metal-ceramic, etc., only if the supporting ones are stamped steel crowns, then the prosthesis is called a stamped soldered bridge. since in this case the intermediate part is not one piece with the supporting crowns, but is soldered to them separately. There are also combined bridge-like prostheses, when the design of one prosthesis usually contains two types of crowns and artificial teeth, for example, metal-ceramic structures are often combined with solid-cast structures; this allows the patient to save money, time for preparing abutment teeth for the prosthesis, and less processing of abutment teeth. Let's briefly look at each type of bridge separately.

Stamped soldered bridge prosthesis. It consists of support stamped crowns and an intermediate part soldered to them. Advantages: low cost in comparison with other designs, this with advantages, perhaps, is all. Disadvantages: all of the above disadvantages of abutment crowns plus possible breaks of the intermediate part at the adhesion points. Heterogeneity of metals, crowns and intermediate parts are made of one metal, solder is made of another, and often these structures are made yellow (the color of gold), and this is the third type of metal, as a result of which there is a high chance of developing the so-called “galvanic effect” in the oral cavity.

Solid cast bridge prosthesis. The pontic and supporting crowns are modeled and cast together and form a single, indivisible structure. Advantages: free from all the disadvantages of the above-described design. Disadvantages: not aesthetically pleasing, more expensive than a stamped soldered prosthesis.

Plastic bridge prosthesis. Made from acrylic plastics. The advantages and disadvantages are similar to those of the plastic crowns described above.

Metal-plastic bridge prosthesis. Metal frame covered with plastic. Advantages: The cost is lower than that of higher quality aesthetic designs. Disadvantages: Low strength of plastics, as a result of which they are susceptible to abrasion; chipping of the cladding is possible; depending on the technology used to manufacture the frame, a fracture of the frame is also possible. Inability to accurately match the color to the remaining natural teeth. They are used to restore the anterior group of teeth; it is not advisable to use lateral teeth due to the low wear resistance of the plastic.

Metal-ceramic bridges. Cast metal frame covered with ceramic cladding. Advantages: high aesthetics. High strength, chipping of the lining is possible, but extremely rare, the bioenergy of the ceramics makes the washing space very small or non-existent. They are used to restore all groups of teeth. Disadvantages: there may be some grayness in the color of artificial teeth due to the metal frame (but this is for aesthetes; most patients do not notice this), relatively high cost.

Bridges made of metal-free ceramics. They are made entirely of zirconium oxide or the zirconium oxide frame is covered with veneering ceramics. Advantages: high wear resistance, lightness, aesthetics, absence of metal. Disadvantages: high cost.

Bridges based on frameless ceramics are not manufactured due to the high fragility of this structure.

Also, the supporting elements of bridges can be not only crowns, but also inlays, onlays and half-crowns.

At our Denta Area dental clinic, we offer the manufacture of all types of crowns and bridges listed above.

That's all for classic non-removable orthopedic dental structures; in the future, this article will be supplemented by a brief description of the so-called microprostheses, i.e., inlays and onlays (veneers), what they are needed for and in what cases they are used, as well as illustrations. We will look at removable orthopedic structures in the second part of the article.