A combined crown is a structure consisting of a metal base and a shell. A composite composition, plastic or ceramics is used as an external coating. The color and texture of the shell is matched to the parameters of natural dental elements. The frame is made of stainless steel or alloys of cobalt and chromium, nickel and chromium. The crown is made using stamping or casting. The thickness of stamped dentures is from 0.3 mm. For cast bases, the thickness reaches 0.4-0.5 mm. Frames of the low price segment are created from dental sockets made of stainless steel. A standard sleeve is taken, broached and forged on a die created from an impression from the problem tooth. When making a cast base, an impression is taken from the dental element and a wax model is made. The internal diameter of the correct frame should exceed the diameter of the tooth stump by 50-100 microns. This guarantees the strength of the connection between the microprosthesis and the element. Cast structures have the specified accuracy. Bases for ceramic or composite cladding are made using standard technology. Today, adhesive liquids are used to create a strong bond between the metal substrate and the plastic. The thickness of the surface layer depends on the material and location on the crown (in the cervical, cutting or central part). To prevent the base from showing through the ceramic layer, white varnish or yellow titanium nitride is applied on top. The popularity of prostheses made of gold alloys is due to biocompatibility and lack of translucency. The veneer performs an aesthetic function and is applied to the vestibular surface.

Metal and plastic

These are inexpensive crowns that have been placed on the front teeth for decades.

The metal base was covered with an inert synthetic. But time has shown the conventional aesthetics of the structures - over time, the coating darkened and the metal became visible. After a couple of years, a painful replacement of the prosthesis was required. Today, metal-plastic crowns are cheap and can be used for the restoration of molars. But their aesthetic life is maximum 3 years. Therefore, this option is recommended as temporary. Before permanent prosthetics during implantation or in other cases when it is impossible to install a permanent prosthesis immediately after treatment.

Indications

The use of combined microprostheses is indicated for all dental defects that require a prosthetic procedure. The products are used for units visible when smiling and during speech. We are talking about the frontal units and premolars of the upper jaw.

Combined microprostheses are indicated in the presence of defects:

- Unit mobility.

- Severe destruction of the supragingival part of the element, which is not spread by filling or using inlays.

- Irreversible change in enamel shade.

- Reduced height of the lower third of the face due to increased wear of dental elements.

- Edentia.

Can be used for implantation and other clinical situations.

Zirconium dioxide and ceramics

Such dentures are flawless and are recommended for installation on the front teeth. The units are stronger than natural ones due to the stable zirconium frame, and the ceramic coating gives them a visual naturalness, ensuring correct light reflection.

But such a tooth crown is expensive. And it’s not always justified. Modern solid ceramics are close in strength to natural enamel. Therefore, in most cases, frameless ceramics, which are indistinguishable from natural units, are chosen for the restoration of the beauty area.

In addition, Cerec porcelain crowns for front teeth can be made within 1.5 hours; the price of this option is more affordable and its aesthetics are high. The artificial units created using innovative equipment will be flawless, you don’t need to get used to them - their parameters are calculated by a computer program taking into account the anatomical characteristics of a particular patient.

What materials are used

The material of stamped crowns must meet certain requirements - sufficient strength, safety for the body, resistance to oxidation, corrosion, ease of processing, low weight. Various metals and alloys are used:

- iron-based (stainless steel, chromium-nickel alloys);

- based on gold;

- based on silver and palladium.

There are several types of stamped structures:

- all-metal

- have a metallic color and shine; - combined

stamped crowns - the front metal wall of the structure is cut out and replaced with a plastic surface. Used for prosthetics of incisors, premolars; - with sputtering

- covering the crown with a thin layer of gold or titanium nitrite, which provides the prosthesis with a golden surface; - with lining

- a plastic or ceramic mass is applied to the finished cap, matched to the tone of the natural enamel.

The stamped crown with veneer is similar in appearance to natural teeth. If the supragingival part of 2-3 adjacent units is destroyed, a single structure is installed on each of them, without soldering into a bridge. The solder area is more susceptible to breakage under chewing stress. In addition, if 1 cap is damaged or deformed, the entire system will have to be removed.

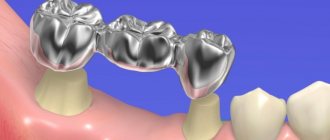

Metal ceramics

If it is necessary to replace molars, ceramics will not be suitable; the material is too fragile and will not withstand the increased load. Therefore, it is more reasonable to install metal-ceramic or zirconium crowns on chewing teeth. The last segment is more expensive. Therefore, many patients choose a metal cast crown coated with ceramics.

Modern frames are made only by casting. This ensures a tight fit of the crown in the remains of the natural tooth, preventing the entry of pathogenic microflora into the tooth.

How are dentures made?

- Therapeutic treatment of the tooth is carried out after its preparation.

- An impression of both jaws is made using plaster or alginate. Plaster impressions are gradually becoming a thing of the past as obsolete; the use of alginate is preferable.

After this, the dentist begins to work closely in the dental laboratory.

- He is given a model of the dentition of both jaws cast in plaster, on which, in case of problems with the bite, the central relationship for its correction is determined.

- Plaster of Paris is placed in the occluder.

- A plaster stamp is cut out of the wax model that is then created, and then a metal one is made according to its sample.

- The sleeve-blank is selected as precisely as possible according to the size of the cast die.

The fact is that the sleeves are produced according to average parameters, and in order to fit the prepared stamp exactly to the tooth stump, there are two ways: choose the exact size or reduce it from the available ones. The sleeve is put on the second die and the fitting work begins, which includes thermal and mechanical effects on the workpiece.

The final check of the finished crown is done in the clinic, where, after fitting, they look at how tightly it fits (without taking into account the future cement layer) to the neck of the tooth. Defects are identified, then the outer surface is ground. If the patient expresses a desire, titanium nitride will be sprayed onto the steel surface.

At the last stage, the finished crown is dried using alcohol treatment, the cement is diluted and injected inside, and it is forcefully pressed onto the tooth stump. To do this, you just need to clench your jaw tightly. The squeezed out excess cement is removed.

When are combined crowns installed?

Metal-ceramics can be installed if a large tooth crown is destroyed; the frame will protect the remains of the molars from excessive loads.

Metal ceramics are installed:

- For a real tooth with a healthy, strong root that has crumbled by 50% or more.

- As part of the bridge structure - crowns on the supporting teeth.

- As a final prosthesis on implants.

The option is quite worthy for maintaining the function of chewing teeth and helping to preserve the structure of periodontal tissues.

But in general, if a tooth is more than 50 percent damaged, it is more advisable to install a Cerec module, and the tooth restored in this way will serve you for many more years.

Reviews

Of particular interest is the use of metal-composite crowns, since they are installed much less frequently than metal-ceramic and metal-plastic crowns.

If you have experience using crowns lined with composite, tell us what their features are, how many years did they last, and what condition were they in? The comment form is at the bottom of this page.

If you find an error, please select a piece of text and press Ctrl+Enter.

Tags dental crowns fixed dentures

Did you like the article? stay tuned

No comments yet

Advantages

Due to the metal base, combined crowns are stronger than real teeth. With proper care, their service life is 15 years

.

Additional advantages:

- They do not lose their shape or shade.

- Visually close to natural enamel. Therefore, they are invisible against the background of neighboring molars when laughing or talking.

- Reliable protection and functionality - you can safely chew your usual food.

- The risk of allergies is minimal (traditionally, up to 2% of people are sensitive to alloys).

When installed correctly, it adheres to the gum and tooth, protecting the units

Price issue

The cost of combined crowns depends, first of all, on the lining material (its brand and manufacturer). Manufacturing technology, status and location of the clinic also affect the price, but to a lesser extent.

Approximate price of crowns lined with different materials.

| Cladding and frame material | price, rub. | Note |

| Ceramic + platinum/gold | From 18 000 | Taking into account the cost of the precious metal |

| Ceramic + Nickel-Chromium/Cobalt-Chromium Alloy | From 8 000 | When using materials from domestic manufacturers - from 5,000 |

| Ceramics + zirconia frame | From 15 000 | — |

| Plastic + Cobalt-Chromium Alloy | From 2 500 | — |

| GRADIA composite + cobalt-chromium alloy | From 8 000 | — |

Manufacturing and installation of combined crowns

To put a metal-ceramic crown on your teeth (cost – 17,900 rubles / tooth), it will take 7-14 days

.

Manufacturing sequence:

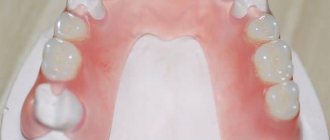

- The tooth is prepared to the thickness of the crown.

- An impression is taken from which a cast crown is made.

- It is advisable to install temporary plastic protection on treated teeth.

- A metal frame is made and tried on.

- If adjustments are needed, they are made, and another fitting follows. When the artificial tooth fits, the metal is coated with ceramic.

- During installation, the tooth is covered with a protective compound, and the prosthesis is fixed with dental cement.

A nuance: the ceramics are applied in layers, each layer is baked in an oven under high temperature. Therefore, the coating is stable and securely attached to the metal base. Contact me at the dentist and we will decide what crown to put on the tooth in your case.

Life time

The service life of veneered products is determined by several factors, including the type of lining material, the professionalism of the doctor, the accuracy of technology, and care of the oral cavity after prosthetics.

The approximate service life of combined models, depending on the type of cladding, is:

- for metal ceramics – 10-15 years;

- for metal composite products – from 5 to 15 years, depending on the grade (brand) of the composite;

- for metal-plastic structures – up to 5 years.

Failure can occur for various reasons. If for metal-plastic products the main danger is the separation of plastic from the metal, then for composite and ceramic products it is cracks and chips.

While composite products can be repaired in the patient's mouth, with metal ceramics there is no other way to correct the problem other than replacing the crown. The same can be said about metal-plastic microprostheses. Detachment of the lining will inevitably lead to food getting underneath and rotting. Therefore, the sooner the prosthesis is replaced, the better.