Zirconium dioxide (oxide) has confidently occupied first positions in the field of dental prosthetics over the past 20 years. Zirconium crowns made from it are distinguished by their aesthetic appeal and the absence of negative side effects after their installation. The use of zirconium in dentistry has solved two prosthetic problems:

- Durability and reliability over a long period of time.

- Full compatibility with periodontium (periodontal tissues).

Externally, zirconium, which is called “white gold” in dentistry, does not look like metal due to the lack of characteristic shine. Zirconium dioxide is a structural composition based on it, white in color with a matte sheen. Currently used for the manufacture of individual crowns, bridges, veneers and inlays.

What are the differences between zirconium crowns?

Crowns made of zirconium dioxide are metal-free structures - one of the types of ceramics. Zirconium is a silvery, grayish metal that is obtained from the naturally occurring mineral zircon.

In dentistry today, metal-free structures are widely used to restore teeth. And models made of zirconium or zirconium dioxide are especially popular. The material is obtained from a natural mineral by stabilization with yttrium and enrichment with aluminum. The resulting zirconium dioxide has very high strength, moderate transparency and a white color without shine. Technologies for manufacturing metal-free ceramics appeared relatively recently, but they immediately gained well-deserved popularity among dentists and patients.

Dental material is produced in the form of fairly soft and plastic blank blocks. The best zirconium crowns are obtained from transparent multilayer blanks of the new generation (Katana line of zirconium discs, Kuraray Noritake, Japan, etc.). The required structure is made from them and its final baking is carried out. After this, the model acquires its main properties: high strength and aesthetics. Externally, artificial teeth made of zirconium are almost no different from natural ones.

And yet, until recently, the high strength of zirconium dioxide did not allow the manual production of monolithic structures. This became possible only with the advent of the latest computer technologies CAD/CAM (computer-assisted design and manufacturing), which includes processing patient data using digital scanning, transferring it to a computer and building an accurate model, and finally manufacturing the desired one on a robotic machine. designs. For chewing units, pure zirconium monolithic structures are used, for the anterior ones, they are covered with porcelain ceramics on top.

What is the basis for comparing these materials?

Why does the question of which is better most often arise about artificial teeth, which contain metal-ceramics or zirconium dioxide? Both of these materials have high strength and wear resistance. They cope well with any load and are suitable for restoring chewing teeth. Modern technologies make it possible to process these materials in such a way that they look good on the teeth located in the smile zone. Yes, yes, provided that structures are created from metal-ceramics with shoulder mass and the use of really high-quality expensive material, this is possible, but we will expand on the topic a little later.

They can be used to make inlays, crowns, extended bridges, as well as fixed structures supported by implants. But that’s where the similarities, strictly speaking, end.

Indications and contraindications for installation

Zirconium dioxide crowns have indications and contraindications for installation. Indications:

- persistent discoloration of tooth enamel;

- destruction of the natural dental unit as a result of caries, trauma, chipped enamel;

- congenital dental anomalies – shape, height, enamel;

- large interdental spaces (trema), including between the front teeth (diastema);

- installation of a prosthesis on an implant;

- intolerance to other dental materials.

Contraindications for installing zirconium dental crowns:

- severe malocclusion – deep bite;

- bruxism (involuntary grinding of teeth) – the risk of rapid wear of antagonist teeth in the opposite dentition;

- very small teeth;

- increased abrasion of hard dental tissues;

- infectious and inflammatory processes in the oral cavity - prosthetics are allowed only after complete treatment;

- diseases that contribute to a persistent decrease in immunity - diabetes, AIDS, oncological processes;

- severe general illnesses and psychoses;

- pregnancy.

Manufacturing stages

Zirconium dioxide is used to make two types of crown designs:

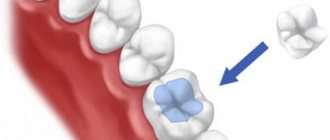

- Monolithic , consisting entirely of zirconium dioxide. They are characterized by increased strength, reliability, and a high degree of abrasion. Recommended for chewing teeth that do not require increased aesthetic beauty.

- Two-layer based on a zirconium dioxide frame with an applied outer porcelain layer. They are used for prosthetics of the frontal area - the “smile zone”. They have the aesthetic color and transparency of a natural human tooth.

High-tech equipment is used to produce zirconium crowns. The process is fully automated and occurs without human intervention using the CAD\CAM method. Includes several stages:

- computer development of a three-dimensional model of the future prosthesis;

- loading the finished 3D model into the control unit of the milling machine;

- creation of a frame made of zirconium dioxide according to specified parameters;

- firing in a special oven;

- application of several layers of porcelain by hand by a technician with sequential firing of each layer;

- manually applying the selected shade of dye;

- final firing.

The shade of the dye is selected according to the color of the patient’s natural tooth enamel. The service life of zirconium crowns is 15-20 years.

Bridges for any number of teeth are made from zirconium dioxide. They are a structure of individual crowns connected together, the outermost of which have a hollow structure. Bridges are mainly made non-removable. However, the possibility of a removable denture is not excluded. The design is supplemented with locks if necessary.

For the manufacture of dentures, three types of zirconium blanks are used, depending on the level of translucency (light transmission):

- Non-translucent with maximum strength up to 1500 mPa. They are used for prosthetics for patients with malocclusion and the absence of several teeth. Finished dentures are colored by placing them in a special composition before firing.

- Increased translucency with a strength of 900 mPa. Used to create individual crowns and bridge structures. Painting is done manually on the inside and outside with special brushes before firing.

- Ultra translucent with a strength of 1100 mPa and a light transmittance of 30%. They are used to create individual crowns and veneers that are particularly aesthetically attractive. The coloring process is identical to the process for products made from non-translucent zirconia compounds. Most often, this variety is used for crowns in the “smile zone”. Can be used to make bridges with no more than three teeth.

Types of zirconium dioxide crowns

Zirconium block blank

Three types of blank blocks are produced depending on the degree of light transmission - translucency or translucency:

- With minimal translucency, maximum strength and resistance to stress. They are used to make dentures for people with malocclusion. In the Katana line these are STML blanks.

- With increased translucency, but less strength. They are used when there is a need for prosthetics of individual units. Suitable for prosthetics when color is of primary importance. The Katana NT brand is suitable.

- With very high transparency - ultra-translucent and with fairly high strength. It makes the best designs for front units. Very aesthetic and do not require ceramic coating. In the Katana line, this is the UTML brand.

There are two types of zirconium models - classic with a zirconium frame and completely made of zirconium.

Models with zirconium frame

Double-layer structures made of zirconium coated with phosphorus ceramics

This type is considered classic. These two-layer zirconia crowns feature a metal-ceramic design: a durable frame made from a monolithic zirconia blank, topped with beautiful phosphorus ceramic. The best models for the smile zone; in appearance they are no different from natural dental units.

Such models are installed on the front sections of the dentition, since the aesthetics of the structure are very important here. They are not suitable for chewing units: there is a high risk of chipping on porcelain ceramics.

Monolithic in full anatomy

Monolithic zirconium models in full anatomy

Zirconium dental crowns, made entirely of zirconium dioxide (monolithic), are less aesthetically pleasing, but they are strong and reliable, so they are installed on chewing units. An interesting fact: to give the prosthesis the desired color, it is painted with special bright paints, and after final firing, the model takes on a natural appearance.

Important – zirconium dioxide manufacturer

In different dental clinics, zirconium dioxide blocks of completely different quality and aesthetic properties are used to make zirconium crowns. These blocks/discs are produced by different manufacturers, and the clinic here can save a lot on the cost of the material. The fact is that standard zirconium dioxide disks/blocks for milling are almost completely opaque and white.

As we said above, the price of such discs starts from 3,000 rubles, which is much cheaper than zirconium dioxide discs with Multi-layer technology, the price of which usually ranges from 10,000 to 17,000 rubles per disc. The “multi-layer” technology implies that the discs will consist of pre-colored zirconium with a smooth color change from the cervical area to the cutting edge, and in addition, due to the addition of yttrium to zirconium, a high level of transparency (transparency) of the material can be achieved.

Below we present a rating of zirconium dioxide discs, which was obtained based on a comparison of the characteristics of discs from different manufacturers, as well as reviews from dentists (link to an English-language study) -

- “Katana UTML” (Japan) is the best material that allows you to make zirconium crowns, which are only slightly inferior in aesthetics to ceramic crowns from “IPS Emax”.

- In 2nd place are the materials “Katana STML” (Japan) and “Prettau Anterior” (Germany), etc.

Recently, more and more new manufacturers of zirconium dioxide blocks with “Multi-layer” technology have been appearing, and it is quite difficult to keep track of them. For example, there is a more budget-friendly (compared to Katana or Prettau) zirconium dioxide Upcera® STML, which is produced by a leading Chinese manufacturer of dental materials and is of fairly high quality.

Hybrid zirconium crowns –

Dental materials are being improved all the time, and manufacturers are trying to combine the positive properties of different materials in one. For example, combining the strength of zirconium dioxide and the aesthetics of lithium disilicate. This is how the group of materials “lithium silicates reinforced with zirconium dioxide” appeared. An example of such materials is

- "Celtra Duo" - manufacturer Dentsply (USA),

- “Suprinity” – (Germany).

Important: therefore, before agreeing to prosthetics with zirconium crowns, you should at least find out about the manufacturer of zirconium dioxide discs that is used by this dental clinic. If we are talking about front teeth, then you need to find out - 1) whether it is a “multi-layer” or NOT a “multi-layer”, 2) whether their zirconium dioxide has a sufficient degree of transparency (transparency), 3) we are talking about monolithic zirconium crowns , or about crowns with the application of a surface layer of porcelain, 4) modeling of crowns on a computer is carried out by a dental technician or “images” are taken from a file library. We hope that our article: Zirconium dental crowns reviews, price – was useful to you!

Sources:

1. Personal experience as a dentist, 2. “Orthopedic dentistry. Textbook" (Trezubov V.N.), 3. National Library of Medicine (USA), 4. "Zirconium crowns" (Gevorgyan Kh.M., Zhidkikh E.D.), 5. https://www.realself. com/,6. https://www.bauersmiles.com/.

Advantages and disadvantages of zirconium dental crowns

The advantages of zirconium crowns include:

- increased strength, resistance to mechanical loads is a very significant advantage; for this reason they are no worse, and sometimes even better, than metal ones;

- corrosion resistance;

- neutrality in relation to galvanic processes;

- free penetration of X-rays - they do not accumulate in zirconium during diagnostic studies;

- tight fit to the natural tissues of the destroyed unit, which gives the structure stability;

- natural aesthetic appearance is one of the main advantages;

- preparation of the unit in the process of preparation for prosthetics is carried out to a minimum extent, since the zirconium model is very thin;

- zirconium dioxide is fully compatible with human tissue and is highly hypoallergenic and does not cause allergic reactions - a very important advantage of the material;

- the prosthesis does not have increased thermal conductivity, so eating hot and cold food does not cause discomfort;

- Zirconium dioxide structures are the option of choice for implant prosthetics.

Disadvantages of zirconium crowns:

- the risk of accelerated abrasion of hard dental tissues on the opposite dentition - in order to smooth out this deficiency, it is not necessary to carry out prosthetics if the patient already has increased abrasion;

- the risk of chipping when porcelain coating the zirconium frame; because of this drawback, the models are not installed on chewing units;

- high price - metal-ceramic models are cheaper.

What is zirconium oxide, or dioxide?

Zirconium oxide or dioxide is used to make crowns, veneers and implant abutments. And although zirconium is formally a metal, structures made from ZrO2 are usually classified as metal-free: they are free from the disadvantages of traditional metal-ceramics, including the visual ones - white zirconium dioxide.

This material has several undeniable advantages.

- High aesthetics.

Zirconium orthopedic structures look much more attractive compared to metal-ceramic ones. They do not have an unnatural gray tint and do not distort the color of the gums above the crown. - Strength.

ZrO2 can withstand the same chewing loads as metal alloys and is thirty times stronger than ceramics. - Hypoallergenic and biocompatible.

Zirconium dioxide is preferable for patients with metal allergies, diseases of the oral mucosa and smokers. - No hypersensitivity.

Zirconium structures do not conduct heat and cold as much as metal ones, so they do not cause discomfort if you eat too hot or cold food.

Installation of zirconium crowns

The installation of zirconium crowns is carried out in stages. The timing of prosthetics is individual and depends mainly on the preparatory stage - the elimination of pathological processes in the oral cavity. All other stages go quickly, since the CAD/CAM system is used - computer analysis of the cast, modeling of the prosthesis based on it, its manufacture on a computer milling machine, and installation take a minimum of time.

A visit to the dentist will be required to treat and prepare the tooth for prosthetics. If the teeth are healthy, everything can be done in one visit and an impression can be taken immediately. But if treatment is required, you may have to visit the dentist several times. After this, two more visits will be required - to try on and install the prosthesis. The standard program for installing zirconium dental crowns includes several successive stages.

Diagnosis and preliminary treatment

At the initial consultation, the orthopedist carefully examines the patient’s dentition and refers him to a consultation with a dental therapist. Here, caries, diseases of periodontal tissues and other pathologies are identified and treated. If necessary, an x-ray examination is performed. Treatment is carried out in accordance with the established diagnosis. If deep caries is complicated by pulpitis, all soft tissue (nerve) is removed from the dental cavity and root canals and a filling is performed.

In some cases, the installation of fillings and stump pin inlays is required. If the tooth is completely destroyed, it is removed and an artificial root is implanted, followed by installation of a zirconium crown on the implant several months after its healing. After treatment, professional dental cleaning is performed and the patient returns to the orthopedist.

Preparation

In order to install a zirconium crown, a layer of enamel equal to the thickness of the zirconium must be removed from the natural crown. Zirconium crowns are very thin, so only a small layer of enamel is removed. The thickness of the zirconium frame is about 0.4 mm, the layer of phosphorus ceramics is 0.6 mm. It is not painful, since there are no nerve endings in the hard tissues of the tooth. But patients with increased sensitivity to pain and fear of dental procedures are given local anesthesia.

Taking an impression and installing a temporary prosthesis

An impression is taken using a 3D scanner in 1–2 minutes, then the data is entered into a CAD/CAM program. The program processes the data and, based on it, creates an accurate model of a zirconium dental crown. The process of creating a model can last from several minutes to an hour, depending on the complexity of the design. A temporary plastic crown-cap is installed on the treated tooth to protect it from damage.

Manufacturing of the structure

CAD/CAM milling machine

A prosthesis is made from a zirconium dioxide blank block based on a computer model on a computer milling machine. The process takes about 15 minutes. The result is an exact anatomical and color copy of a natural tooth. After this, the resulting structure is fired until densely sintered. If it is a two-layer model, a phosphor ceramic coating is applied on top and fired again.

Fitting and final installation

When visiting the orthopedist again, a zirconium dioxide crown is tried on. Since its production using computer technology is highly accurate, in most cases the prosthesis is installed and fixed immediately. If any inaccuracies are identified, the orthopedist eliminates them himself or sends them back to the dental laboratory indicating the exact correction parameters. To install the prosthesis, the patient will need to visit the orthopedist again.

The prosthesis is fixed using special dental cement. The entire crown installation process takes about half an hour.

Zirconium crowns: price in Moscow and regions

For zirconium crowns, the price below is indicated for 2022. The price already includes all expenses - with the exception of the cost of possibly necessary therapeutic preparation of the tooth for prosthetics, as well as the cost of a temporary plastic crown (1 temporary crown - from 2000 rubles).

- 1 zirconium crown per tooth – price not less than 30,000 rubles.

- 1 zirconium crown on an implant – from 30,000 to 40,000 rubles.

Important: unfortunately, these are the prices you should expect for zirconium crowns with good aesthetics. In this case, much more expensive zirconia blocks with a gradient of color and transparency (multi-layer) will be used, and you should also expect that the computer models of yours will be drawn by hand, and not taken from a “library of ready-made images”. But you can easily find clinics that offer the cost of a zirconium crown from 15,000 or 20,000 rubles.

Of course, in this case much cheaper zirconium dioxide blocks will be used - bright white in color, without a gradient of color and transparency. And even with superficial application of layers of porcelain (in order to improve aesthetics), you will receive crowns of a milky, unnatural shade that will stand out against the background of your own teeth. An option to save money and at the same time get decent aesthetics is another option for prosthetics (especially pressed ceramics “E-max”).

Alternative prosthetic options - the price of ceramic crowns made of lithium disilicate IPS E-max, also made using CAD/CAM equipment - will also average about 30,000 rubles. The cost of crowns made from IPS E-max PRESS, made by pressing, will average from 20,000 to 24,000 rubles.

→ Cost of metal ceramics

Possible problems and complications

As a rule, if the installation protocol is strictly followed, there are no complications. Immediately after installing a zirconium prosthesis, you may experience discomfort, tension in the masticatory muscles, and minor problems with speech. All this goes away within a few days. But sometimes the following problems arise while wearing a prosthesis:

- Insufficient fit of the crown to the tooth is extremely rare, since computer technology implies high precision in making the model. This is where zirconium crowns differ significantly from metal-ceramics, since the fit accuracy of the latter is much less. And the larger the space between natural dental tissues and the prosthesis, the greater the risk of developing caries and loosening the structure. If such a complication occurs, the structure is removed, treatment and re-prosthetics are carried out.

- Caries and inflammation of the periodontal tissues may be associated with poor preparation for prosthetics. At the same time, the doctor decides whether the prosthesis needs to be removed or whether treatment can be carried out through a small hole in it.

You should consult a doctor if the following symptoms appear:

- redness and swelling of the gums near the denture;

- the tooth under the crown hurts a lot, chills and increased body temperature have joined in;

- loosening of the prosthesis.

Advantages and disadvantages of metal-free ceramics

- Safety. Crowns made of this ceramic material do not cause cases of hypersensitivity, because Zirconium oxide has similar chemical and physical properties to bone tissue.

- Durability. Dental structures based on zirconium dioxide last at least 15 years. Moreover, they do not deform during wear, do not lose their shine, and if microcracks form, they restore the original structure at the molecular level.

- Naturalness. Crowns do not differ in shape or color from real teeth.

- Ease of installation. The tooth is ground down minimally for a crown. At the same time, the gap between the tooth and the crown is only 30 microns, which reduces the risk of damage or destruction of the supporting tooth.

- Tight fit to the gum and abutment tooth. Zirconium crowns are adjusted to the very gum, and no pathological changes occur in the tissues. The possibility of a tight fit allows you to form a perfectly straight dentition.

The only drawback of zirconium crowns is their relatively high cost. Not every dental clinic installs and manufactures metal-free crowns, because... they require the necessary equipment to produce crowns.

Caring for zirconium crowns

It is very easy to care for zirconium tooth crowns, just like you would care for your own teeth. After installing zirconium crowns, it is enough to follow the following rules:

- do not chew nuts, candies and other hard foods; but with zirconium crowns you can eat apples and nibble on chocolate;

- brush your teeth twice a day with a regular toothbrush and toothpaste;

- rinse your mouth with water after eating;

- if there are food particles left in the interdental spaces, you need to remove them using dental floss or an irrigator - a device for cleaning the dentition with a jet of water under pressure;

- professional dental cleaning should be carried out twice a year;

- control by an orthopedic dentist - at least once a year.

With proper care, zirconium dioxide crowns will last a very long time.

Prosthetics based on zirconium dioxide

Since 1969, zirconium dioxide has been used in medical practice. Then it was used as a hypoallergenic material in the manufacture of hip joint heads. And since 1993, zirconium dioxide has confidently entered dentistry and revolutionized the field of prosthetics.

An even row of teeth is not only an attractive appearance, but also health. However, losses also occur, and then the question arises of how to replace the “departed” or how to protect his “shaken health.”

Why zirconium dioxide crowns?

Zirconium dioxide is a chemical derivative of zircon, a mineral that is actively used in jewelry, a white material (can be of different shades) with a high degree of transparency, similar to the internal tissues of a natural tooth. It is obtained by chemical processing of the zircon mineral. Those. Zirconium dioxide structures are primarily metal-free.

All over the world, crowns and structures based on zirconium dioxide are considered the most aesthetic and prestigious prosthetic option. This is not surprising: metal-free ceramics allows you to create a visual effect of complete resemblance to a natural tooth, even the refractive index of light will be as close as possible to that of “native” teeth. If you look at this crown in the light, you can see that it has some transparency around the edge - exactly like a real tooth!

Metal-ceramic structures, alas, cannot produce a similar effect. Metal coated with ceramics still remains metal and does not look so natural and not so beautiful! It is not for nothing that world stars, public, successful people prefer metal-free ceramics when it comes to prosthetics.

In Russia, zirconium dioxide has been used in dental prosthetics for about 15 years, but still not every dental clinic can boast of having such a service, since its use requires special qualifications of an orthopedist, dental technician and, of course, the availability of the necessary equipment for the full production cycle zirconium dioxide dentures.

The main advantages of zirconium dioxide:

- increased strength: zirconium dioxide is an ultra-strong material. Therefore, there is no need to be afraid that the artificial tooth will break or crack at the most inopportune moment;

- durability: crowns and frames made of zirconium dioxide can last for many decades without needing restoration, because they do not deform over time, unlike metals;

- ideal biological compatibility: zirconium dioxide does not cause allergic reactions, inflammation or gum recession. According to histological studies, after 6 months of wearing zirconium dioxide crowns, no pathological changes were found in the oral cavity. Zirconium dioxide is several times more biocompatible than gold;

- light transmittance: crowns and frames made of zirconium dioxide will transmit light at approximately the same level as happens with natural teeth;

- transparency: the level of transparency of zirconium dioxide corresponds to that of natural teeth;

- zirconium dioxide has excellent mechanical properties - namely, high bending strength and crack resistance;

- minimal grinding of teeth: if you get a zirconium dioxide crown, your own tooth will suffer minimal damage. The fact is that the thickness of the zirconium dioxide crown is only 0.4 mm. Therefore, the volume of your natural tooth will be preserved almost completely.

- minimum period of prosthetics: since most of the manufacturing process is automated, the number of necessary manipulations and, accordingly, the time spent by the dental laboratory on creating the prosthesis is significantly reduced;

- lightness of crowns: crowns on zirconium dioxide are lighter than crowns with a metal base;

Zirconium dioxide prosthetics: indications

- restoration of one tooth;

- restoration of several teeth by installing a dental bridge;

- dental prosthetics during dental implantation;

- prosthetics in the presence of allergic reactions to metals;

- prosthetics with high aesthetic requirements.

Zirconium dioxide prosthetics: contraindications

Like all medical procedures, the installation of zirconium dioxide dentures has a number of contraindications. These include: too small teeth, deep bite and involuntary teeth grinding syndrome.

Stages of prosthetics and production

Very high precision of the crown fit and its fit to the ground tooth, which is achieved through the use of CAD/CAM technology , minimizes the risks of caries developing at the crown/tooth interface and the penetration of saliva and microorganisms under the crown.

When designing structures made of zirconium dioxide CAD technologies , which avoid inaccuracies and manual casting errors. When fitting crowns created by hand casting, the marginal gap will be 100-300 microns. And that's okay. When installing zirconium crowns made using computer technology, the marginal gap will be only 30 microns. Naturally, crowns made from zirconium dioxide are as comfortable and high quality as possible.

To manufacture structures from zirconium dioxide, CAM technology - this is an ultra-precise technology that does not allow human intervention and, naturally, eliminates errors that a person might make. The structures are made on a milling machine from a single piece of zirconium dioxide using the CNC (computer numerical control) system. The production time for one unit is about 2 hours.

- Before proceeding with dental prosthetics using zirconium dioxide, a thorough examination of the oral cavity is carried out. Therapeutic preparation of supporting teeth is carried out. If necessary, old and low-quality fillings are removed, followed by filling of open root canals; simply put, treatment is carried out.

- Next, the doctor grinds down the supporting teeth for crowns. The qualifications of the doctor and his experience in working with this type of prosthetics are very important in this matter.

- then an impression of the ground teeth is made, a model is made, which is scanned using a 3D scanner, processed with a special program (CAD), which models the image of the future crown and transfers it to milling equipment (CAM). At the crown modeling stage, the orthopedic surgeon can also make adjustments, if necessary. Thus, a 3D model of the patient’s teeth is created.

- the result is loaded into a milling machine, which, without human intervention, automatically cuts out an ultra-precise zirconium frame for the future crown from a single block of zirconium dioxide.

- the resulting crown frame undergoes heat treatment (agglomeration), due to which high strength of the material is achieved.

- then the dental technician carries out a multi-stage procedure of veneering the crown with special ceramics (color-matched to the needs of a specific clinical case), surface layers are applied over and over again, each layer is sintered in an oven at high temperature;

- final processing of the crown in the laboratory, grinding, the crown acquires a natural shine.

Based on the above characteristics of zirconium dioxide, we can conclude that at the moment it is the most favorable material for creating denture structures of any complexity.

Today, dental crowns made of zirconium dioxide are the most modern way to restore teeth. The dentures are as accurate, safe and natural as possible. This is an option that will last for decades without causing any hassle or inconvenience. Caring for such crowns is no different from any other types of fixed dentures: regular cleaning, rinsing, using an irrigator, as well as regular preventive examinations at the dentist.

By wearing crowns or dentures made of zirconium dioxide, you can be sure that you will not develop an allergic reaction, rejection, or inflammatory process. Smiling, talking, laughing, you don’t have to worry about your appearance - your teeth will look natural and flawless.

How widespread is this material in Pskov?

Until recently, for most Pskov residents this option was simply financially inaccessible: a zirconium dioxide crown cost 2-2.5 times more than a metal-ceramic one. First of all, this is due to the fact that dental laboratories were forced to order the production of their structures in other cities. An impression was taken on site in the clinic, and, as a rule, scanning, making a 3D computer model, and milling were carried out externally. This lengthened the deadlines and increased the cost of the finished work.

We are pleased to inform our patients that we have purchased new expensive equipment - a CORiTEC 450i milling machine made in Germany, working using CAD/CAM technology. You can talk about the advantages of this device for a long time, starting with how convenient it is for dental technicians and ending with how fascinatingly technologically the milling process takes place in it: simultaneously in five planes, without the participation of the “human factor”.

Now in our dental laboratory, specialists carry out the full cycle of manufacturing crowns based on zirconium dioxide, since they have everything necessary for this at hand.

The qualifications and experience of our dental laboratory staff, coupled with the productive capacity of the equipment, allow us to perform work not only for our own patients, but also to serve third-party dental organizations.

We invite everyone interested in this type of prosthetics to M-Dental for consultations with orthopedic doctors. They will draw up a treatment plan and determine all stages and methods of restoration.

Call JV "M-Dental" right now and make an appointment with an orthopedic doctor, you can also make an appointment through our website.

Prices

The cost of a ceramic zirconium crown consists of:

- the need for and scope of therapeutic measures in the process of preparation for prosthetics;

- type of prosthesis (classic two-layer or monolithic in full anatomy); zirconium crowns for front teeth with ceramic coating are more expensive;

- use of high-precision equipment for the manufacture of prostheses;

- the need for preliminary installation of an artificial root - implant;

- having your own dental laboratory or more expensive contractual relationships;

- qualifications of specialists;

- reputation and geographical location of the clinic.

On average, the price for installing a crown on a zirconium tooth in dental clinics in large cities (Moscow, St. Petersburg, etc.) ranges from 25 to 50 thousand rubles.

If you need to make a crown on a damaged tooth, or restore an entire area with several missing teeth, you may face the problem of choosing a material for the prosthesis. Of course, only an orthopedic doctor can give the necessary recommendations, taking into account the depth of the lesion and the location of the tooth. But in order to better understand this issue, we will talk about the modern material used for the manufacture of orthopedic structures - zirconium dioxide.

If you want crowns to be no different from the rest of your teeth, then zirconium dioxide is what you need!

We keep up with the times and practically do not use metal and metal-ceramic crowns in our work. Most of our guests, when they come for a consultation with an orthopedic doctor, themselves ask for dental prosthetics with more durable and aesthetic designs.

What is zirconium dioxide?

Zirconium is a metal, but its dioxide is not. This compound contains transparent crystals that are not subject to change when exposed to water or temperature changes. Zirconium dioxide itself is soft - this allows you to create products of any size and any shape from it. But after the sintering (sintering) process, zirconium dioxide becomes strong and hard, not inferior to metal in these characteristics. This material is approximately 2-4 times stronger than ceramics used in prosthetics. It is thanks to this that structures made from it can withstand high loads and can last for decades.

A zirconium crown is a prosthesis that has a bright white color and is particularly durable. It is installed to replace the lost tissue of the crown part of the tooth or even the tooth or teeth itself (if prosthetics is carried out on an implant or using a bridge).

The melon type of structures is relatively young. In 1994, Matt Anderson introduced the Procera system to the dental community, a new technique for making zirconia crowns.

Zirconium crowns do not have a metal frame, so they can let light into the tooth, making them look more natural.

In addition, zirconium dioxide is not subject to corrosion and oxidation, and as a result, the gums above the crown do not darken over time (as happens with metal-ceramic dentures).

From all of the above, we conclude that zirconium crowns have clear advantages, namely

- The strength of the zirconium dioxide structure allows for the creation of extended bridges

- Thickness of tooth tissue preparation Possibility of keeping the tooth “alive”. Since the frame of zirconium dioxide crowns is quite thin (namely about 0.3-0.6 mm layer), it is not necessary to depulpate the tooth (remove the nerve), the pulp chamber is not damaged during the preparation process.

- Biocompatibility. Zirconium dioxide is a hypoallergenic material that combines ideally with tooth tissue, which avoids the occurrence of pathological processes. There is no need to injure the gum and “hide” the edge of the crown under it, since there is no dark metal edge on the crown. Also, the absence of metal eliminates pigmentation of the gums due to oxidation.

- No sensitivity to temperature changes.

- The prosthesis very accurately conveys all the anatomical features of the structure of the teeth.

- Durability. The warranty period for a zirconium microprosthesis is on average about 2-3 years. But for patients who maintain oral hygiene and regularly undergo professional cleaning by a hygienist, zirconium dioxide caps last 10-15 years. Moreover, they do not change shape and color throughout their entire service life.

- For more than 30 years, the use of zirconium dioxide in medicine has proven the biocompatibility of zirconium dioxide with any tissues of the body (as we said earlier). Including in the oral cavity!!!

- One of the most important qualities is also the absence of galvanosis effect.

- The highest aesthetic indicators also influence the choice! Color rendition and some transparency of the design allows you to make a prosthesis that is not noticeable in the oral cavity.

This type of prosthesis also has some disadvantages.

- The cost is primarily due to the complexity of manufacturing, as well as high quality and a fairly long service life, and the use of expensive computer equipment to create a prosthesis.

- Possibility of chips or cracks, but this is due to failure to follow recommendations for the use of prostheses or installation of a prosthesis in the presence of contraindications.

When is it not recommended to install zirconia crowns?

- for some malocclusion pathologies

- with hypertonicity of the masticatory muscles

- with bruxism

During the consultation, the doctor will determine whether there are contraindications for the use of orthopedic structures made of zirconium dioxide and will offer the best solution to the problem. Do I need special care for installed zirconium dioxide crowns?

There is no rule for cleaning teeth covered with zirconium crowns that differs from caring for your own teeth. You need to understand that home oral hygiene should be carried out 2 times a day (in the morning after tomorrow and in the evening before bed), both for natural teeth and for teeth covered with orthopedic structures. Of course, in addition to a toothbrush and toothpaste, you need to use dental floss and mouth rinse. An additional hygiene product is an irrigator. We recommend using this device for those who have orthopedic structures, including those made of zirconium dioxide.

Of course, professional oral hygiene 2 times a year is recommended. Home care is not enough to maintain proper hygiene. Hard-to-reach areas of the oral cavity, periodontal pockets, bridges - all this requires the work of a hygienist. Our dentists use special tools to perform professional hygiene with zirconium dioxide crowns.

Compliance with the recommendations of an orthopedic doctor for the care of crowns made of this material guarantees their long service life.

Our clinic has been specializing in orthopedic structures made of zirconium dioxide for many years. We offer patients single crowns, bridges, and crowns on implants made from this material. In many respects, zirconium dioxide, products from which do not deform over time, is superior to any dental alloys. Dentures made from this material are difficult to distinguish from the enamel of your own teeth in appearance, and are comparable in strength to this fabric. Being manufactured using high-precision equipment, these products are perfectly similar in shape to natural teeth and have a perfect fit to your own dental tissues.

Metal-ceramic crown or zirconium crown – which is better?

To choose a material for prosthetics, you need to consult an orthopedic doctor. Which is better, a zirconium crown or a metal-ceramic crown, and what is their difference, can be seen from the following table:

| Prosthetic material | Metal ceramics | Zirconium |

| Appearance | Mediocre | All types of prostheses are aesthetic |

| Strength | There may be chips in the ceramics | Chips of ceramics with two-layer crowns |

| Fabric compatibility | Possible allergy or tissue irritation from metal | Fully compatible |

| Color change | Over time they acquire a grayish tint | Does not change color - a very important advantage |

| Preparation | A significant layer of enamel is removed, up to 2 mm | A very thin layer, up to 0.5 mm with a monolith and about 1 mm with a two-layer prosthesis |

| In what areas of the dentition are they installed? | On the sides. Not applicable for anterior areas due to color changes | In any area; Monolithic dentures are placed on the chewing units, with a ceramic coating on the anterior ones. |

| How suitable for implantation | There are contraindications | Ideal for implant prosthetics |

| Making a prosthesis | Mostly manually | Using computer technology on a robotic milling machine |

| Price | Average | Above average |

Liberals or conservatives: how to fix zirconium structures?

The world is becoming increasingly polarized and a change in any views leads to the development of significant and often not very tolerant discussions. There is an ongoing debate in dentistry as to which is better: cementation or adhesive bonding?

Of course, when cementing it is possible to avoid all the nuances and problems associated with bonding, however, adhesive fixation also has a number of extremely significant advantages. Of course, every doctor wants to ensure the reliability of retention and long-term success of his designs and restorations, but often he does not delve too deeply into the scientific facts regarding a particular fixation mechanism. With regard to zirconium dioxide crowns, given its hardness, it is believed that almost any type of cement will be suitable for their fixation. However, this approach did not provide ideal long-term results, especially in cases of inadequate preparation or when the patient has parafunctional habits. New, more transparent versions of zircon have expanded the possibilities of its use in aesthetic areas. But at the same time, a decrease in the opacity of zircon is also associated with a decrease in its bending strength. More transparent zircon is often fixed with cement with a double polymerization mechanism, or composite cement, and this is also associated with certain risks of violating the adhesive processing protocol.

New point of view

Zirconium has become a popular material of choice among many clinicians seeking esthetic yet simple restorations at an affordable price for both clinician and patient. This material is effectively included in the working arsenal of most practitioners when performing partial and full-contour crowns, as well as bridge structures. With proper preparation and cementation, the survival rate of such structures is quite high and predictable. However, clinicians have also observed outcomes in the form of debonding, restoration fracture, opacification, and chipping when implementing the classic cementation protocol for zirconia restorations. In cases of insufficient preparation or in case of excessive occlusal loads, it is recommended to fix zirconium structures using cements with a dual polymerization mechanism. Under the direct control of the clinician, two factors that increase the long-term clinical success of zirconia restorations are retention preparation and the use of dual-curing cements chemically formulated with 10-methacryloxydecyl dihydrogen phosphate monomer (10-MDP). 10-MDP is currently considered the strongest bonding agent available for zirconia and is found in some bonding systems, primers and self-polymerizing cements.

Concerns about potential pulpal irritation and biological intolerance to certain cements have led professionals to turn to more bioinert materials. These often include the function of releasing fluoride and/or calcium, and are represented by certain composites, cements, spacers, liners and even adhesives. That is why, in recent years, much of the research has been aimed at developing a biocompatible material that would have antimicrobial properties, promote remineralization, and at the same time contain a 10-MDP monomer for high-quality adhesive bonding of full-contour zirconia restorations.

One of these materials is modern composite cements with a dual polymerization mechanism, which, on the one hand, contain 10-MDP monomer, and on the other hand, release significant amounts of calcium and fluoride. Thus, they promote the release of ions, which in turn reduce the degree of microbial invasion, reduce acidity levels and promote remineralization.

“Adhesivism” versus “cementalism”: full-circuit zircon structures

A middle-aged female patient sought dental care. She had distal crossbite, interdental caries, midline malposition, and discoloration (Figure 1). It was planned to carry out restorations using full-contour zirconium restorations: monolithic and more opaque in the distal areas, and more transparent in the anterior areas (photo 2). The condition of the surrounding soft tissues was acceptable; root discoloration was visualized in the area of the 8th tooth, since this tooth had been treated endodontically many years ago (photo 3). After removing the metal-ceramic structure, it was possible to identify an area of pronounced black discoloration, which needed to be corrected before fixing the crowns (photo 4).

Photo 1. The patient came in with a desire to improve his smile profile.

Photo 2. Visualization of differences in tooth profiles.

Photo 3. The central incisor was previously endodontically treated, after which a metal-ceramic crown was installed on it.

Photo 4. To cover the area of discoloration, the vestibular part of the stump and the cervical area were prepared to form a place for applying the opaque composite.

Reduction of dentin tissue in such cases only leads to an even greater “darkening” of the surface, so preparation was carried out in the range of 1-2 mm on the vestibular side and slightly in the subgingival area. A universal adhesive (All-Bond Universal, Bisco) was applied to the surface in several layers, which was thoroughly rubbed in and polymerized (photo 5). After this, a layer of opaque flowable composite was applied to the surface of the tooth, and then a portion of the composite was applied in a shade corresponding to the surrounding dentin (photo 6).

Photo 5. Application of adhesive agent.

Figure 6: After dissection, clinical photographs were taken and then sent to the laboratory.

The preparation was carried out with a diamond bur (NeoDiamond, Microcopy), providing a clearance of 1.5 mm on the occlusal side and forming a chamfer-shaped ledge. The occlusal plane on the mandible was adjusted to eliminate the crossbite with the final restorations. Impressions were taken using A-silicone (Panasil, Kettenbach) and sent to the laboratory along with clinical photographs, a bite register and a silicone template obtained using a dentofacial analyzer (Kois Dentofacial Analyzer, Panodent). Temporary crowns were cemented with temporary cement (Zone Free, Pentron), after pre-treating the cores with 2% chlorhexidine solution (Cavity Cleanser, Bisco). Initial testing of the final restorations was carried out on models (Figure 7). Crowns were made of high-strength opaque material for the distal teeth, while crowns for the anterior teeth were made of more transparent zircon dioxide (photo 8). After removal of the temporary restorations, the teeth were cleaned with a special paste (Preppies, Whip Mix) and a 2% chlorhexidine solution (Cavity Cleanser, Bisco). The restorations were then tried on using special try-in pastes to confirm that the desired shade could be achieved after final bonding (Figure 9).

Photo 7. Evaluation of the preparation on the model.

Photo 8. View of the restorations on the model.

Photo 9. Cleaning teeth after removing temporary crowns.

Dual polymerization composite cements containing 10-MDP provide a reliable bond to clean zirconia surfaces without the need for additional separate primers or adhesives when the tooth surface is phosphate-free. However, during fitting of zirconium restorations, phosphates from oral fluid almost always contaminate the tooth surface and compromise the adhesive bond (Figure 10). To remove such contaminants, a special cleaner (ZirClean, Bisco) is used, which is then washed and dried.

Photo 10. Trying on zirconium crowns.

Photo 11. Cleaning crowns before fixation.

“Politically” correct biologically reasoned fixation

To fix the restorations, self-adhesive cement based on a calcium silicate composite (TheraCem, Bisco) was used (photo 12). This cement contains 10-MDP monomer, has a “natural” tint and provides a strong bond to dentin and most modern dental materials such as etched lithium disilicate and zirconia. The high level of calcium in the cement structure makes it slightly opaque and white in color, but does not critically change the color of the final restoration (photo 13). The calcium and fluoride releasing features and physical properties of TheraCem make it an excellent choice for the routine luting of full-contour zirconia or lithium disilicate restorations (Figure 14). The notable features of this calcium silicate cement are its ease of cleaning and excellent clinical performance. After initial chemical curing, the material is easily removed and is then light cured at the crown margins. One week after fixation, the soft tissue condition and aesthetic profile of the patient's smile was acceptable (Figure 15). The patient’s subjective expectations were fully justified and, thanks to the approach used, the doctor was able to achieve biotolerant fixation of zirconium restorations, which is the most acceptable for surrounding tissues (photos 16-17).

Photo 12. Fixation was carried out using calcium silicate self-adhesive cement with a dual curing mechanism.

Photo 13. Bonding was carried out starting from the front teeth and moving back one crown at a time.

Photo 14. View of the crowns after fixation.

Photo 15. View 1 week after fixation.

Photo 16. Improved smile profile.

Photo 17. Improved smile profile and healthy soft tissue.

By Jack D. Griffin, Jr., DMD

TOP-6 advantages of prosthetics with zirconium crowns

Prosthetic dentists highlight five main advantages of restoring a smile with zirconium dioxide crowns:

- Strength is no worse than that of metal ceramics.

This quality is achieved thanks to the stage of zirconium firing in a furnace. Thus, there is no risk that the crown will crack at the slightest pressure on it. The material zirconium dioxide is 30 times more durable than ceramics. On the other hand, if you bite into food carelessly (the same nuts, seeds, etc.), a zirconium crown is not immune to accidental splitting; - Minimal preparation.

Since a zirconium dioxide crown has thinner walls (the average thickness of the frame is 0.4 mm) than metal-ceramics (metal-ceramic crowns have walls up to 2 mm thick), teeth are prepared for it to a minimum; - No allergies or irritation.

Zirconium is considered one of the most “loyal” materials to the environment in the oral cavity, and therefore allergies to such crowns are extremely rare. In most cases, people immediately get used to the new prosthesis; there is no metallic taste in the mouth; - Combined with an implant.

Modern implantation systems imply the presence of zirconium dioxide abutments, which guarantees impeccable gum aesthetics; - Reduced load on the gum and root.

The zirconium frame weighs an order of magnitude lighter than the metal one, and therefore the gums and roots are protected from unnecessary overloads; - Flawless natural aesthetics.

For zirconium dioxide crowns, the shade is selected at the level of the frame. Thus, the frame does not become translucent, as in metal ceramics, and does not oxidize over time. Also, over time, a dark rim around the gums does not appear. The zirconium material of the prosthesis demonstrates resistance to dyes and does not change its tone depending on the lighting.

Recommendations for choosing colors

To obtain a natural effect after prosthetics, you need to pay special attention to the shade of the products. How to choose the color of zircon crowns if it seems that there is no significant difference between them?

The shade of the dentures is selected in advance, even before the construction itself is manufactured. The specialist offers the patient several options, comparing the estimated shades with natural teeth, but even if it initially seems that the denture will look natural, there may be a discrepancy, since after production the actual shade may differ.

To get the perfect result, it is better to get advice from experts first. You can also read reviews about what the color of dioxide crowns will be after prosthetics, and how to choose the appropriate option.

This is especially important if the prosthesis is installed on the anterior area of the jaw. The patient should be guided not only by the shade of the enamel of the opposite dentition, but also by the adjacent teeth. Before the procedure, you can look at a computer-processed photo that will show what zirconium crowns look like on your front teeth.