Classification of elastic polymers

Elastic polymers are made from different materials:

- acrylic;

- polyvinyl chloride;

- vinyl chloride with butyl acrylate;

- siloxane or silicone;

- fluoroelastomer

Elastic polymers belong to one of two groups - plastics with high or low temperature polymerization. Available in the form of a gel, elastic sheets, a set of powder and liquid, or in the form of a laminated gel or in cartridges. The powder is a copolymer of acrylic monomers.

Molding fluid is a mixture of acrylic monomers or methyl methacrylate containing a plasticizer and some organic solvents. The second option is a liquid made from acrylic monomers - for fast-hardening plastics.

Main base plastics and their properties

Ethacryl (AKR-15) is a base material that is a copolymer of methyl methacrylate, ethyl methacrylate and methyl acrylate, colored in a color similar to that of the oral mucosa. It has increased plasticity at the time of molding and sufficient elasticity after polymerization. Used for removable denture bases, individual impression trays, and phantom jaw models.

The powder (polymer) is plasticized due to internal plasticization by introducing “methacrylate” into the macromolecule. The liquid is a combination of three monomers - methyl methacrylate, ethyl methacrylate and methyl acrylate in a ratio of 89:8:2.

Polymerization of the polymer-monomer composition is carried out, as a rule, in a water bath.

The base material Ftorax is a high-temperature polymerization plastic and belongs to graft copolymers. The material is “grafted” on the basis of acrylic resins from fluorine rubber and compares favorably with other acrylates by its higher physical, mechanical and chemical properties.

Ftorax has a static bending angle that is 20% higher than AKR-15 and 15% higher than Akrel, and the specific impact strength is higher by 9% and 11%, respectively.

It should be noted such properties as slow aging, slight water absorption, preservation or slight change in linear dimensions, lack of toxic effects on the microflora of the oral cavity, as well as on the body as a whole. Here we need to add a shorter adaptation period to prostheses made from Ftorax and a good imitation of the color of the oral mucosa [Kharchenko SV., 1971].

Ftorax powder is a fine, pink-colored, suspension and graft copolymer of methacrylic acid methyl ester and fluorine rubber. The liquid is methacrylic acid methyl ester containing a cross-linking agent - diphenylopropane dimethacrylic ester.

The main disadvantage of Ftorax is the significant content of residual MMA monomer, which, apparently, is the cause of fairly frequent toxic-allergic reactions to this material.

Acronil has increased impact resistance, low water absorption, and good technological performance. The powder is a methyl methacrylate copolymer grafted onto polyvinyl acetal, and the liquid is methyl methacrylate containing a cross-linking agent. Acronil contains an inhibitor and stabilizer.

Acrel is a copolymer with “cross-linked” polymer chains, which gives it increased physical and mechanical properties. The formation of a network (cross-linked) structure of the polymer occurs during the polymerization process with the help of a cross-linking agent, which is introduced into the monomer and participates in the reaction only during the polymerization of the molding mass. Acrela liquid, in addition to methyl methacrylate, contains a cross-linking agent and an inhibitor. The powder consists of fine polymethyl methacrylate plasticized with dibutyl phthalate.

Bakryl is a high-strength acrylic plastic that, compared to other polymers, has greater resistance to cracking, abrasion, impact strength and high bending strength. The powder is polymethyl methacrylate modified with elastomers. The liquid is methyl methacrylate with inhibitors. Plastic has good manufacturability.

Colorless plastic for prosthesis bases is a polymer based on polymethyl methacrylate, free of stabilizer, containing an antiaging agent, and consists of powder and liquid. It differs from other produced base materials in its increased strength and transparency. Technological manipulation of plastic does not differ from the generally accepted ones.

Imported analogues of base plastics supplied to Russia correspond to domestic ones in terms of basic physical and mechanical indicators. For example, the base plastic of hot polymerization Paladon-65 is supplied (Germany) in the following configuration:

— pink monomer and polymer;

— monomer and polymer of pink color with veins;

— monomer and polymer of a pink, cloudy color with streaks of “vessels”;

- monomer and colorless polymer.

Impact-2000 is a hot-curing acrylic plastic for the bases of removable dentures produced in the USA and has high impact resistance and resistance to deformation and fatigue failure under the influence of bending loads.

Such plastics as Magnum (Germany) are also known; Mega L (Germany); Futura acrylic-2000 - plastic (Germany); QC-20, Selectaplus, Trevalon, Trevalon-S - pink acrylic plastic (USA), Akron MSi - acrylic plastic in different colors (pink, colorless, pink with veins of “vessels”) (Japan), etc.

Polyvinyl chloride materials

Polyvinyl chlorides, high-temperature polymerization plastics, are available in powder-liquid configurations and in the form of a laminated gel. These materials are considered the ancestors of elastic polymers. In structure, they are copolymers of vinyl chloride with other monomers. A high degree of elasticity is achieved through external plasticization.

Such plastics resist abrasion better than silicone and acrylic, but are less attached to a rigid base. The presence of a plasticizer in the composition causes shortcomings of the material - its migration and aging.

What not to do with a plastic prosthesis

Some people, due to ignorance and a desire to refresh the appearance of the orthopedic structure, make mistakes when caring for it. As a result of incorrect actions, you can get the opposite effect. To prevent this, when caring for a prosthesis you cannot:

- use sharp objects to remove food debris from various recesses and protrusions of the structure;

- soak the denture in vinegar, hoping to refresh and lighten its colors;

- use bleaches to clean artificial teeth, retainers and bases;

- use potassium permanganate, furatsilin and other coloring antiseptic agents for disinfection;

- store the product in chlorinated water, especially if there are metal parts;

- Avoid prolonged exposure of the prosthesis to direct sunlight.

If you follow these simple recommendations, the design will maintain a neat appearance throughout its entire lifespan.

Silicone base materials

These materials are characterized by stable elasticity. The cold polymerization material is technologically advanced and can be worked with without the need for a dental laboratory. It is inert and does not swell in the oral cavity, is not susceptible to the influence of microflora on the lips, does not contain plasticizers, and therefore retains its original elasticity for several years.

Cold vulcanized silicone is a filled silicone composition in the form of a paste and a catalyst liquid. The first two liquids in the composition are vulcanization catalysts, the third is a soil adhesive. The paste contains silicone rubber and organosilicon dioxide, as well as a dye.

Silicone materials are used as a temporary soft layer for a period of up to 4 weeks. Adhesive must be used before application. The substance ages quickly and loses elasticity because it has little resistance to abrasion. Silicone polymers are characterized by insufficient adhesion to the acrylic base and low tensile strength. They are labor-intensive to correct, have weak shock-absorbing properties and are expensive. The mechanical strength of the material is increased by selecting rubber with optimal molecular weight and reinforcing fillers.

Periodic deeper cleaning and disinfection

Full care of removable plastic dentures also requires additional hygienic treatment. To carry it out, you need to place the structure in a special solution once or twice a week. It's easy to prepare. The pharmacy sells special tablets for cleaning removable dentures; instructions are included with each product. Typically, the procedure is as follows:

- you need to throw the effervescent tablet into a container of water;

- place the removable denture there for three to five minutes;

- to enhance the effect, you can clean the structure with a soft toothbrush dipped in the solution;

- After treatment, wash the prosthesis under running water.

A freshly prepared disinfectant solution contains antiseptic and proteolytic (protein-breaking) substances that help disinfect surfaces and remove pigment deposits from them. This cleaning is effective for removing soft stains, it refreshes artificial teeth and gums, and removes stubborn stains. But if there is hard tartar or old stains on the surface of the base or crowns, then effervescent tablets will not help; more intense exposure will be required.

Disadvantages of elastic base polymers

- Rapid aging.

- Loss of strength and elasticity.

- Inability to polish the elastic layer - especially after correction of a denture on implants or another type.

- Unhygienic due to excessive looseness.

- Insufficient marginal contact of the elastomer with rigid base plastics.

- Difficulty in processing with cutting tools and problems with base correction.

To get rid of these shortcomings, new methods of modifying plastics are being developed, aimed at modifying the physical and mechanical properties and increasing the strength of the connection between the hard and elastic layers. Using topcoat varnishes, they improve external characteristics, reduce surface tension, and help increase the fixation of the prosthesis.

Elastic acrylic: new generation removable dentures

Having lost several adjacent teeth or completely lost teeth on the jaw, patients think about removable dentures. This is a quick and inexpensive way to get back to chewing thoroughly, smiling beautifully, and speaking clearly.

Pros and cons of removable dentures

- Fast production

- The price is several times lower than the design on implants

- Inferior to implantation in aesthetics and convenience

Even after the rapid development of dental implant technology, removable dentures are in demand among the population. Doctors and dental technicians were looking for a way to make them more comfortable.

Previously, materials for removable dentures could be divided into 2 categories:

- flexible,

- Tough.

Nylon dentures are flexible

Nylon is pliable, soft, elastic. It is pleasant to the touch and allows you to create very beautiful, natural-looking dentures with translucent gums. The partial nylon denture is attached using dental clasps - soft translucent hooks that cling to the supporting teeth.

Advantages:

- Aesthetic,

- With a comfortable and discreet fastening

- High elasticity: partly takes the shape of the gum, so it sits comfortably.

Flaws:

- It cannot be adjusted after production or adjusted to changes in the gums.

- Over time it absorbs odors and dyes.

From these two disadvantages follows the third - a nylon prosthesis lasts less than other types of dental prosthetics. It rarely breaks, and more often it no longer fits the shape. Due to the fragility of nylon dentures, CosmoStom doctors recommend them only for temporary replacement of teeth. This prosthesis is called a “cosmetic bag” and is worn during the implant healing period.

Acrylic dentures - hard

Acrylic and its hypoallergenic brother Acry-free do not have the disadvantages of nylon. An acrylic prosthesis with a rigid base is easy to recognize by touch: it cannot be bent with your fingers.

Advantages:

- Does not absorb odors and dyes;

- Can be repaired: even if split in two, it can last for a long time;

- It can be polished and adjusted to suit the shrinkage of the gums;

- Lasts longer than nylon.

Flaws:

- Does not bend, is less comfortable in the mouth, takes a long time to get used to;

- Attaches to wire clasps, which are more noticeable.

Clasp dentures - rigid

These prostheses have a metal arch, which allows the load to be distributed more evenly. And artificial gums are made of acrylic.

Advantages:

- all the advantages of acrylic dentures;

- various types of fastenings, including invisible ones.

Flaws:

- higher price, especially for options with aesthetic fastenings.

New generation – elastic acrylic

Now a new material has appeared in dentistry - polymethylacrylate, elastic acrylic. However, it is new only for dentistry. Polymethyl acrylate has been used in ophthalmology before: in the manufacture of contact lenses and even artificial eye lenses.

In the CosmoStom laboratory, technicians use polymethyl acrylate from Yamahachi (Japan). It melts well, without burning, and takes the desired shape, and then can be easily corrected.

Elastic acrylic combines the advantages of acrylic and nylon: it is moderately flexible and at the same time quite stable.

Advantages:

- Lightweight, flexible prosthesis is comfortable to wear,

- Strong, durable, subject to adjustment and repair,

- Does not absorb odors and food dyes, hypoallergenic,

- Convenient fastening: invisible soft clasps,

- Good aesthetics: translucent, imitates the veins of natural gums.

Manufacturing features. This material is close in composition to acrylic, but during the processing process it goes through more stages; it is additionally melted, uniformly increasing the temperature by more than 1000 degrees. At this moment, unnecessary impurities that could cause an allergic reaction evaporate. It also breaks down the compounds that made the acrylic too rigid.

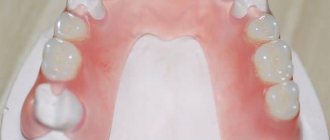

From molten polymethyl acrylate, a dental technician carefully, using a special syringe, forms a denture according to the individual model of the patient’s jaw.

A prosthesis made from Japanese elastic acrylic has a more complex, multi-stage production technology. Therefore, the price is higher than that of nylon and acrylic dentures. However, due to its long service life, elastic acrylic is more profitable than nylon.

Smiling, chewing, diction

We will restore them using implantation or removable prosthetics.

Transparent gum

Nylon and elastic acrylic look very natural

Soft clasps

Hooks on the denture made of elastic acrylic comfortably and discreetly hold onto the supporting teeth

Polymethylacrylate

Elast. acrylic looks like this until a technician turns it into a prosthetic

Your orthopedic dentist will tell you which prosthesis is best to choose for your individual case. Here are some general recommendations.

Choose elastic acrylic if:

- A regular acrylic prosthesis is uncomfortable for you; you couldn’t get used to it.

- The nylon prosthesis did not suit you in terms of service life.

- You need a partial denture and the attachments will be in the smile area.

- You need a full upper denture and it is not supported by implants (hence it has an artificial palate).

Sign up for a consultation with an orthopedic dentist and enjoy your new smile!

| Price, ք | With a discount, ք |

| Partial removable denture Vertex (Netherlands) with reinforced cast arch made of CoCr Magnum (Italy) | 22550 |

| Clasp removable denture Vertex (Netherlands) with clasps | 42445 |

| Partial denture made of elastic acrylic Yamahachi (Japan) | 30190 |