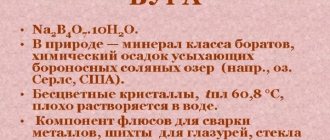

Description of the substance

What is borax substance? Many minerals containing sodium tetraborate have been studied. Such deposits include:

- borax or sodium tetraborate tinkal decahydrate;

- kerite;

- Borax sediment is formed during the drying up of salt lakes (Searles, lakes of Turkey);

- minerals belonging to the borate class, containing calcium, sodium and similar elements other than borax.

Varieties of borax

There are two options for this material. In solid form, borax appears as a powder with small granules of a small fraction with a white color. The flux will not spread during application and can be precisely positioned in the required metal-to-metal junction areas.

Diluted borax has also been used for light metals. In some cases, liquids are very convenient, because you just need to dip a small part into the solution. In addition, the liquid form allows the use of borax even at low heating temperatures.

In some cases, it is advantageous to use a mixture of fluxes with borax included in the composition for the special characteristics of the base metal and special requirements for the connection.

Slime with tetraborate from glue stick

With this method, you do not need a microwave or steam bath, but the main component must be kneaded well. Very little activator is required, since there is little glue. Tetraborate can be diluted with water in advance so as not to over-thicken the slime.

Components

- 15 g glue stick,

- 1-2 drops of sodium tetraborate,

- 0.5 tsp. water,

- 1.5 tsp. shampoo.

Cooking method

- The glue stick needs to be released from the packaging and squeezed in your hands until it softens.

- Sodium tetraborate is added to this mass.

- And you need to knead it again until it lags behind your hands.

- Next, water is added to the base.

- It also needs to be mixed into the slime.

- The last component is shampoo, which is added in 2 doses.

- Now the mass needs to be completely kneaded.

Composition and properties

The chemical nomenclature of soldering borax indicates that it is a crystalline hydrate of the sodium salt of tetraboric acid. If the substance contains 10 water molecules, then it is called sodium tetraborate decahydrate. In simple words, it is a salt that is surrounded by a shell containing 10 or 5 water molecules.

A temperature of 64 degrees causes decahydrates to melt and lose water in the process. Borax is dehydrated at a temperature of 380 degrees Celsius. Tetraborate is characterized by withstand heating up to a temperature of 742 degrees and melting when it increases.

Borax contains sodium chlorine, barium chlorine and, in some cases, boric acid. Flux in the form of a solution has a high ability to dissolve metal oxides, as well as fatty films and anything unnecessary that can prevent the adhesion of materials.

Thanks to the use of borax during soldering, many products are produced without defects.

Receipt

The substance is obtained by recrystallization of natural borax or kernite (tetrahydrate); interaction of boric acid with sodium carbonate; interaction of natural borates with sodium carbonate and bicarbonate when heated.

Updated: December 5, 2022 at 00:00

(c) AgroXXI Directory

Very often, pharmacy clients are interested in remedies for sore throats, which can be bought without a prescription and used independently. Gargling is one of the most affordable and safest options for treating a sore throat.

Kinds

Based on appearance, welding drills are divided into 2 types.

- Solid. In powder form, flux has the form of solid fine fractions. This shape makes it easy to lay borax on a metal surface before the soldering process, while the substance does not spread. Solid borax is sold in boxes that are sealed, thereby protecting the substance from moisture and the negative influence of the environment. In the powder fraction, borax is white.

- Divorced. This type of borax is considered the most suitable for light metal and its alloy. The substance is the same powdered borax, but dissolved in a liquid. This feature of the flux makes it possible to use it at low soldering temperatures. Using diluted borax is quite simple: small metal elements are dipped into it and then soldered. This flux is popular in jewelry, as well as when working with wires and contacts.

Prevention

Seizures in the corners of the mouth are not dangerous in themselves, but they can be symptoms of serious diseases, so they always deserve attention.

- give up the habit of licking your lips;

- treat and control metabolic or internal organ diseases;

- constantly use protective cosmetics that maintain a normal level of hydration and protect lips from irritating environmental factors;

- strictly observe the rules of oral hygiene.

When examined by a doctor, you need to find out the cause of the inflammation, and what measures to take to reduce the likelihood of their occurrence. Author: Yulia Lapushkina, dentist List of references: 1. Nirima Oza, Jitendra J Doshi. // Angular cheilitis: clinical and microbial research. //Indian j dent res. // November-December, 2022. 28(6) 2. Marco Cabras, Alessio Gambino, Roberto Broccoletti. // Treatment of angular cheilitis: a narrative review and clinical experience by the authors. //Oral Dis. August, 2022. 3. Mahmoud Husni Ayesh. // Angular cheilitis caused by iron deficiency anemia. // Cleave Wedge J Med. // August, 2022.85 ( 4. Justin R. Federico, Brandon M. Basehor, Patrick M. Zito. // Angular cheilitis. 5. Kelly K. Park, Robert T Brodell, Stephen E. Helms. // Angular cheilitis, part 1: local etiology. // Kutis. // June, 2011. 87 (6).

Advantages and disadvantages of the product

Let's start with the pros:

- The drug is extremely affordable. The cost of a bottle of borax does not exceed $1, which is several times cheaper than other antiseptics and combination products.

- The drug is non-toxic, well tolerated and does not cause serious side effects.

- The product can be used in problem categories of patients: children, pregnant women, nursing mothers.

- The drug is effective, especially in gynecology. Glycerin has a softening and anti-inflammatory effect, relieving itching and burning, and boric acid helps restore the acidic protective environment of the vagina, stimulating the growth and reproduction of beneficial lactic acid bacteria.

Of water

In this recipe, before mixing, the water should be slightly warmed up so that the soda dissolves in it better and faster. It is more convenient to place all components into the bottle through a funnel. Then the entire measured amount will be used and not spilled or spilled.

Proven recipe

- 1 tbsp. l. water,

- 1 tsp. soda,

- 1 tbsp. l. boric acid.

Cooking method

- The specified amount of soda must be poured into a plastic bottle.

- Water is also poured there.

- Another essential component is boric acid.

- The bottle must be closed and shaken to mix both liquids and dissolve the soda in them.

- Then the composition is filtered through a cotton pad to get rid of the remaining particles of soda, and the activator can be used.

Watch this video for a DIY recipe for sodium tetraborate from water:

Scope of application of the drill

Sodium tetraborate has been actively used for the following purposes:

- as a flux during soldering and melting of metals;

- in analytical chemistry studies as a standard substance for determining the level of acid in a solution. Borax is also used to establish the characteristics of metal oxides;

- widespread use in the creation of glazes, enamel, glasses for optical instruments and decoration;

- the powder is used in pharmaceuticals and paper production;

- is a natural preservative and means for disinfection and control of parasites;

- is a component in the chemical industry to create household cleaning products;

- relevant application in the creation of cosmetic products;

- borax is used as a base for creating boron;

- the substance is a component for creating insulating building materials;

- in light industry, sodium tetraborate is applied to the product before the painting procedure.

Using a drill in everyday life

Borax can be found in most grocery stores. It is a relatively inexpensive product, making it an excellent choice for many household projects.

Use of sodium tetraborate as a medicine

The substance is very effective in controlling pests: cockroaches, ants and other household insects. The mixture is ready by mixing equal parts of powder with sugar. Sugar helps attract beetles and borax exerts its detrimental effect on the insect. It is recommended to keep the substance in hard-to-reach places, away from pets and children. Optimal places: under stoves, refrigerator and sink. Borax also works well against mice. You just have to apply the powder in the areas where the mice are located, and the borax will rid you of the pests. You can also sprinkle the solution on the carpet and vacuum it to eliminate the presence of fleas or treat the mattress to get rid of bedbugs.

Borax will get rid of rust. Mixing 1 cup of powder with 2 cups of water and 1 tablespoon of lemon juice makes an effective anti-corrosion agent. The paste-like solution is applied to the rusty items for about 15 minutes. After which the rust can be easily removed by mechanical friction.

Sodium tetraborate is a universal cleaner. Two tablespoons of borax are mixed with 2 cups of water to create an all-purpose cleaner. The solution can be applied in a spray bottle and used to clean kitchen surfaces and bathroom tiles and ceramics. Borax is great for removing very stubborn stains. Borax will help remove stubborn stains from the floor.

Borax will allow you to flush your home plumbing fixtures. Simply place ½ cup of borax into the drain with a few cups of warm water. Borax breaks down dirt that gets stuck in pipes. This will not only remove excess and unclog the drain, but also disinfect the system.

Application in forging and forge welding

Borax is actively used as a flux for forging and forge welding. The powder is a source of boron oxide, with excellent antioxidant properties. Borax can, if necessary, remove small cracks during metal processing, change the shape of a product, or when heated during artistic forging and blacksmithing of metal. The substance is classified as a high temperature flux. The processed workpiece with borax is characterized by more wear-resistant characteristics and durability.

Using borax in soldering.

During the melting of borax at a temperature of 700-900 °C, the surface of the material being processed is cleaned, and all excess inclusions are dissolved in the flux. During the processing of a material by forging, a thick layer of scale is gradually created. In some cases, the metal being processed may completely burn due to overheating of the part. But by using a thin layer of borax, this scenario can be avoided.

In industry

Industrial enterprises find the following uses for this substance:

- as a raw material for the production of boric acid;

- as an antiseptic in the production of bulk insulation materials such as “Ecowool”.

- as a means for determining the concentration of acid solutions;

- in welding production as a component of flux;

- in the mechanical engineering industry as a component of antifreeze and various lubricants;

- in glass production;

- the fabric is treated with sodium tetraborate for better dyeing;

- Borax is a component of almost all cosmetic products.

Using borax in the soldering process

In addition to household use, borax is a popular raw material for soldering. High temperature flux is produced as a finely dispersed powder. When heated above 700 degrees Celsius, the flux flows into a liquid state and becomes solder. I’ll tell you about the pros and cons of this flux in the table below.

| Pros of borax flux | Cons of solder |

| The elements being connected do not need to be heated to the same temperature. | After the borax solder cools, salt-type deposits form on the surface of the seam, which will have to be cleaned off from time to time. This is not very convenient for hard-to-reach places. |

| The quality of the roller is high even when connecting different materials. For example, metal and non-metal. | |

| The roller can be destroyed if necessary by reheating the borax to the melting point. | |

| The peak heating temperature of 700+ C will not allow copper parts to warp + the characteristics of the weld with this solder are higher than usual. | Flux absorbs moisture very well. A closed storage container doesn't even help. Too wet solder reduces the quality of the roller several times. |

| Capillary soldering itself is considered the best solution for connecting small and medium-sized parts. | |

| The powder mixture makes it possible to achieve a high level of seam strength. |

To learn how to use Borax without jambs, you need to maintain clear proportions when applying. For beginners in welding, this can be problematic, so gaining practical experience with such solder is extremely important.

Rules for soldering with technical borax:

- The base for applying boron powder must first be cleaned. The welder gets rid of various greasy stains, wax and other debris from the surface of the future seam. For this procedure I use regular sandpaper. It's quite enough.

- The soldering iron tip needs to be preheated before touching the solder.

- To form a reference seam, I advise you to heat the workpieces to the same temperature.

- The tip of the soldering iron should heat both sides of the elements being connected.

- Do not skimp on solder to form a quality connection.

- When the solder begins to flow, the soldering iron tip is temporarily removed from the joint location.

- After applying the bead, the joined elements cannot be moved until they have completely cooled. When working with transistor components, you should use “crocodiles” that will act as heat sinks, thereby reducing the risk of temperature damage to the filling.

If dry joints occur, the roller must be melted and the seam redone. After finishing work with solder, the tip of the soldering iron is cleaned. When working with copper parts, cleaning the edges of the elements being joined is especially important.

What tools and materials are used in the borax soldering process:

- soldering iron Used to heat solder + sometimes for the connections themselves. Sometimes it is more convenient to heat the elements with a gas burner;

- stand. To position the soldering iron while it is heating up or is inactive. There are a lot of variations of stands for this instrument on the Internet, so choosing one that is convenient for you will not be any problem;

- rag or sponge. Consumables needed to clean the soldering iron tip;

- fine grit sandpaper. Used for stripping joints to which solder will be applied;

- crocodiles. The clamps play an auxiliary role as radiators;

- burner. Needed when soldering pipes.

Also, to improve the quality of the seam, I advise you to use boron flux, which will contain fluoride or chloride elements. When soldering pipes, the elements being connected must be heated for at least 25 seconds.

How to make borax with your own hands?

Lizun with tetraborate analogue - Naphthyzin

Naphthyzine as a thickener is much weaker than tetraborate, but it still needs to be used carefully and little by little. In this recipe, it is especially important to mix the base well at each stage. Then the slime will be soft, smooth and shiny.

Components

- 40 ml PVA glue,

- 2 tsp. water,

- 0.5 tsp. body lotion,

- 1 tbsp. l. starch,

- 6 tbsp. l. shower mousse,

- 5-6 drops of liquid pigment,

- 1 pinch of soda,

- 1-1.5 tsp. Naphthyzin drops.

How to make slime with your own hands

- In a clean bowl, combine PVA glue and water.

- The next component is body lotion.

- It needs to be mixed into the mixture with a spoon.

- Then starch is added.

- After this, you also need to mix the base with a spatula.

- To add airiness, add shower mousse.

- After another stirring, you need to pour in the dye.

- When the base acquires color, soda is poured into it.

- The mass must be stirred again.

- Then Naphthyzin is poured into it in portions.

- The base must be stirred with a spatula until the glue stabilizes.

- At the end, be sure to knead it with your hands to rid the slime of excess moisture.

What is it and what is it for?

Soldering borax is a high-temperature type of powdered flux that is used when joining metal products by soldering. Melting of this substance can occur under the influence of temperatures exceeding 700 degrees Celsius. Soldering borax has its own GOST, according to which it is manufactured and its characteristics are regulated.

The substance in powder form looks very similar to salt, in other words it is called sodium tetraborate. The synthesis of borax occurs naturally, and its extraction is carried out from salt lake deposits.

The use of this substance is quite wide, but most often it is used for soldering copper pipes.

The advantages of using borax include the following:

- the materials that are planned to be processed may have different temperature conditions;

- obtaining a high-quality, reliable weld not only between metals, but also between metal and non-metal surfaces;

- ease of soldering seams if necessary to separate parts;

- when soldering, the parts do not warp or deform;

- increased productivity during capillary soldering;

- obtaining smooth and durable seams even from a craftsman with little experience.

The disadvantages of sodium tetraborate are as follows:

- release of a large volume of salts, which harden on the metal at high speed;

- absorption of moisture from the environment;

- the difficulty of selecting the right amount of borax for an inexperienced welder.

What to do if the craft with this activator does not thicken?

In the process of creating slimes, sometimes situations arise when the slime does not work out at all. This happens due to poor proportions or the use of low-quality ingredients.

- If the slime turns out to be too liquid and you can’t get it out of the bowl, then you need to add a little more sodium tetraborate to the composition.

If the slime, on the contrary, has become too thick, then it is mixed with water and kneaded in your hands again.

To avoid such situations, it is necessary to check the expiration dates of borax and glue. They should not be older than two months!

Source

Description and external signs

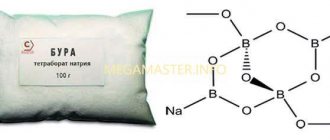

Borax mineral is an aqueous sodium borate with hydroxyl. It is also popularly known as boric salt. In Asian countries it is called tincal. This substance resembles almost colorless crystals. Origin of the name: from the Arabic word bauraq - translated as “white”. The form of release of borax in pharmacies and hardware stores is a white fine-crystalline powder.

Chemical composition

The components of borax are the sodium salt of boric acid and a strong base (water, sodium). Chemical formula: Na2(B4O5)(OH)4 8H2O

The practical significance of borax is to serve for the extraction of boron.

Molecular weight of the substance: 381.37; Density: 1.7; Specific gravity: 1.69 – 1.8; Maximum birefringence: δ=0.025; IMA classes: borates.

physical characteristics

The color of borax can vary: it can be white with a gray tint, yellowish, less often with a blue or greenish tint. When exposed to light, the crystals are almost colorless. The gloss is matte resinous. The stone looks as if it has been oiled. In terms of hardness, it is a very brittle mineral. Borax is highly soluble in water and forms a slightly alkaline, sweetish solution. Melting point – 60°C; at 320°C the crystals lose water and a white powder is formed.

Slime with tetraborate analogue - liquid for lenses

With this method of making slime, the more homemade foam, the more voluminous the toy will be. Therefore, it is better to use thick shampoo. A liquid glue, like Lucha, will do, but it works. You can also replace PVA with stationery.

What to make from

- 1 tsp. shampoo,

- 1 tsp. water,

- 85 ml PVA glue,

- 0.5 tsp. acrylic paint,

- 1 pinch of soda,

- 1.5-2 tsp. liquids for lenses.

How to cook

- Shampoo is poured into a plastic bottle.

- Water should also be sent there.

- Close the bottle and shake until foam appears in it, and put it aside for a while.

- Glue is poured into the working container.

- You need to attach foam from the bottle to it.

- The composition must be mixed.

- Then it is tinted by adding and stirring pigment.

- Soda goes into the liquid next.

- After using it, the base is stirred again.

- All that remains is to pour in the lens solution.

- Now you need to stir with a spoon until the glue curls.

- The collected mass is crushed by hand.

We recommend reading about how to make slime from sodium tetraborate. From the article you will learn about slime recipes made from shaving foam, corn starch, toothpaste, film mask, glycerin and other ingredients. And here is more information about how to make slime from glycerin.

Using sodium tetraborate is the easiest way to thicken slime, but you can do without the finished product. After all, with Teymurov’s spray, boric acid, solutions for lenses, Naphthyzin, Levomycetin, the toy turns out no worse. And, of course, even tetraborate substitutes should be used carefully and little by little.

Similar articles

- How to make slime or slime without sodium tetraborate...

We make slime or slime without sodium tetraborate (borax/borax) with our own hands. 16 simple, proven recipes at home. List of ingredients. Read more - How to make slime or slime from sodium tetraborate: 20...

We make slime from sodium tetraborate (borax/borax) with our own hands. Simple, proven recipes for slimes with tetraborate, glue and without glue at home. Read more

- How to make slime or slime from boric acid...

8 proven recipes for boric acid slime and slime. How to make slime with your own hands at home. Simple, step-by-step slime recipes. Read more

- How to make slime or lizun from glycerin...

6 proven recipes for slime and slime made from glycerin. We make real slime with our own hands at home. Read more

- How to make slime or lizun at home...

25 proven, step-by-step slime recipes at home. We make real slime with our own hands. Read more

Flaws

- After use, a deposit of salts forms, which must be removed mechanically;

- It is necessary to choose storage areas that are free of moisture, since high humidity will cause the flux to deteriorate;

- To prepare the material for use, you need to spend time and choose the right proportion, which can lead to errors.

Varieties of Borax

There are two main varieties that relate to the appearance of the material. The first option is the solid form. Borax soldering flux is supplied in the form of a powder with fine solid fractions. Thanks to this, it is easy to lay it on the metal surface before soldering in the required quantity and it will not spread at the same time. This variety is supplied in a special box that protects the material hermetically from the penetration of moisture and other foreign factors. Fractions are white.

Soldering borax in powder form

The second type, which is more often used for lighter metals and their alloys, is diluted borax. In this case, you are offered the same material, but dissolved in liquid. Due to this, it can be used at lower soldering temperatures. Using this type is also easier, since small parts are simply dipped into the liquid, after which they can be soldered. This is used both in the jewelry industry and in other places where small items are worked. Contacts, wires and other types of equipment come into good contact with dissolved flux. Despite the fact that the principle of using borax for soldering in liquid form is somewhat different from the standard one, they have almost the same effect.

There are also varieties in the form of mixtures, when other fluxes are also used. This is necessary in cases where it is impossible to achieve the desired results using one substance. Proportions and composition depend on specific goals. Most often it is combined with boric acid.

Composition and physicochemical properties

The composition of borax for soldering includes sodium chloride and barium chloride, in some cases boric acid is added to it. It is not used in its pure form for all procedures, since this would require too high a melting point. Drill soldering powder is a high-temperature flux, so its main property is resistance to high temperatures. It is worth noting that the material perfectly retains its chemical properties even at a lower concentration than what is supplied. Thus, the flux solution has a fairly high level of dissolution of the oxides of all base metals for which it is used.

It can also dissolve fatty films and other unnecessary things that will interfere with the normal soldering of the material. Brown soldering protects against many types of defects that can occur in work.

Specifications

There are two main grades of the substance, which are defined according to GOST as grade A and grade B:

Soldering of metals is carried out by first removing traces of oxides from their surface. Fluxes are used for this. They should prevent oxidation when heated and encourage good flow of molten solder.

For soldering copper products, borax solder ideally meets all requirements. The substance has been known since the Middle Ages. It was mined in the lakes of India and Tibet, then transported to Europe, where it was used for processing fabrics and leather, and producing glass.

Borax is widely used for working with metals. When manufacturing or repairing metal products, borax soldering is carried out. First of all, the method is used for parts made of copper and brass. A special type of this flux is used when repairing jewelry.

Recipes:

1. To disinfect, you need to prepare a dark pink solution of potassium permanganate and rinse your mouth with this liquid. 2. To treat gumboil, you need to rinse your mouth with a solution of baking soda and iodine every hour (4 drops of iodine and 1 teaspoon of soda per glass of water). 3. For diseases of the oral cavity, you can use alcohol tincture of propolis. Rinse solution: 20 drops of tincture per glass of water.

For many people, oral hygiene ends with brushing their teeth. However, cleaning your tongue is also necessary and important. Plaque and bacteria accumulate on it, from which caries develops and an unpleasant odor appears.

Regular tongue cleaning helps to avoid diseases such as stomatitis, gingivitis, caries and even periodontitis. Now we will look in detail at why you should clean your tongue and how to do it correctly and effectively.

Brushing your tongue twice a day not only cleanses it of bacteria. This cleaning eliminates four problems.

- Prevents the development of caries

by preventing microorganisms from producing acid that destroys enamel. - Removes bad breath

because bacteria do not produce odorous substances. - Removes plaque

- a breeding ground for bacteria. - Increases the sensitivity

of taste buds - a clean tongue senses the flavors of food and drinks more clearly.

When caring for your tongue, it is worth remembering that not every coating is a sign of some problems. There is also a healthy plaque that can be easily removed with proper hygiene.

Healthy plaque

easy to distinguish by several characteristics.

- It is formed

in the morning, after eating or during thirst; - disappears

after cleansing; - changes color

due to coloring by products; - through it you can see

the surface of the tongue; - it doesn't smell

.

Unhealthy plaque can be a symptom of many health problems: diseases of the stomach and intestines, dysfunction of the liver and kidneys, infections in the body (whooping cough, foot and mouth disease, scarlet fever, pityriasis rosea), as well as a consequence of taking antibiotics.

This is what characterizes an unhealthy plaque

.

- It remains

even after thorough cleaning; - It smells

bad ; - very dense and quickly restored

after cleaning; - regardless of food, the color ranges

from yellow to brown; - accompanied by

redness, swelling and cracks of the tongue, nausea, bitterness in the mouth, gastrointestinal upset, etc.

If the plaque is deep yellow or gray-yellow, you should pay attention to the gastrointestinal tract - you may have gastritis, ulcers, pancreatitis. And if frequent and severe heartburn occurs, the plaque will turn yellow-orange.

But we must remember that harmful plaque is not always caused by some disease. It can appear due to an unhealthy lifestyle: smoking, a large amount of dyes in foods, poor hygiene, even due to caries and bleeding gums. Brushing your tongue with a toothbrush will not solve this problem - you need to contact a specialist to understand how to proceed.

Do not use regular toothbrushes for cleaning - they will not be able to remove plaque. It is better to pay attention to special tongue cleaning products.

Scrapers

The most common devices are scrapers. The tips of the scrapers are made in the shape of a spoon. They are usually made of plastic, sometimes with stiff bristles. The flat shape prevents the gag reflex that may occur when brushing the root of the tongue. This scraper needs to be changed every six months.

Irrigator attachments

Tongue attachments are also made in the form of a spoon. The irrigator, unlike a conventional scraper, delivers a stream of water, which additionally washes the surface of the tongue.

Attachments for electric brushes

Most brush manufacturers offer special attachments for their products to clean tongue deposits. As a rule, they have a flat, textured rubber surface.

Tongue gels

You should not clean your tongue with toothpaste - it is intended for teeth. Pastes contain abrasives and menthol, they can irritate the mucous membrane. Special gels that gently dissolve plaque and also disinfect the oral cavity are better suited for the tongue.

Recommendations for adults

- Proceed with the procedure only after brushing your teeth

and rinsing your mouth. - Use special tools

: scrapers, nozzles and others. - Clean your tongue using sweeping movements

and light pressure. - Start from the root of the tongue

and end with the tip. - Do not brush your tongue with cross movements and do not press

too hard - this can damage it. - Don't forget to clean the instrument

after the procedure. - Be sure to rinse your mouth

with water.

Should children have their tongues cleaned?

Children also need tongue care, but not earlier than 3–4 years. For younger children, tongue cleaning is pointless. They don’t eat junk food, especially not in the same quantities as adults, and they don’t drink tea and coffee. Until 3–4 years of age, normal oral care is sufficient. From 3–4 to 8 years

This is how you should clean your tongue.

- Move from the root of the tongue to the tip

with smooth sweeping movements, with even weaker pressure than with adults. - Similarly, clean the sides

of the tongue and the inside of the cheeks. - Be sure to rinse your mouth

.

From 8 years old

You can now use scrapers.

Side effects

A side effect to the drug can only appear if there is a high sensitivity to the components.

These include:

- Itching

- Weakness

- Possible skin rashes

- Convulsions

- Digestive disorders

- Dermatitis

- Failure of the menstrual cycle

- Abdominal pain

- Cardiopalmus

- Anemia

You should stop using this drug if you experience any side effects and seek immediate medical attention.

Contraindications

- Mechanical damage to the skin and mucous membrane

- Breastfeeding and pregnancy

- Hypersensitivity to individual components of the drug component

- Drug intolerance

Authenticity

Qualitative reaction. To 5 ml of a 4% solution add 0.1 ml of a 0.1% phenolphthalein solution; the solution turns red. When adding 5 ml of glycerin, the 85% solution should become colorless.

- Qualitative reaction. To 0.2 g of the substance add 1 ml of concentrated sulfuric acid, 3 ml of 96% alcohol and mix. When ignited, the mixture should burn with a green-edged flame.

- Qualitative reaction. A 4% solution should give a characteristic reaction A to sodium (General Pharmacopoeia Monograph “General reactions to authenticity”).

Slime with tetraborate analogue - washing gel

The recipe uses concentrated Persil gel, but Perwoll or Laska are suitable for the same purpose. You will need a lot of activator. Still, it should be poured in little by little, and the base should be thoroughly stirred, first with a spatula and then with your hands.

What do you need

- 100 ml PVA glue,

- 1 pinch of powder dye,

- 6 tbsp. l. shaving foam,

- 2-3 tbsp. l. Persil liquid washing gel.

Cooking method

- The glue is placed in a bowl and dye is immediately added to it.

- You need to mix everything so that the color of the future slime appears.

- Next, shaving foam is squeezed into the composition.

- The base must be mixed again.

- Then Persil gel is poured in parts.

- Stir the mixture with a spoon until it thickens.

- Then it is kneaded manually until it comes away from the skin.

Disadvantages of flux

When working with borax, a characteristic deposit remains on the surface of the base metal, which must be mechanically cleaned off. Borax is susceptible to moisture and should be stored in a dry place. It is necessary to carefully prepare the flux in advance so as not to spoil the product.

Types of soldering flux

Tools and materials

The soldering technology uses a number of components.

- A soldering iron is used to heat joints that are to be soldered. Solder has a lower melting point than the metals that are being joined. Solder melts when heated with a soldering iron.

- Borax acts as a flux to prevent oxidation of the metals that are combined.

- The solder used to join copper pipes has a necessary acid base that is suitable for pipes but is corrosive to electronic connections.

- A stand on which you can hold a hot soldering iron. There are various stands. It is important to always keep the hot soldering iron in place when not in use.

- A sponge or rag that is used to clean the tip of an iron.

- Fine sandpaper used to clean connections before soldering.

- Alligator clips can be used as heat sinks if necessary.

- Burner if pipes are soldered.

Tools for soldering

Thus, the use of borax is effective in domestic conditions for cleaning surfaces and parts, and also as an antiseptic. The ingredient is often used for soldering various parts as protection against oxidation and corrosion prevention. Low cost and widespread use have allowed the substance to be used in many areas of industry and installation services.

Toxicological properties and characteristics

Warm-blooded animals and humans. Sodium tetraborate penetrates the skin and has a mild cumulative effect. Does not have a local irritant effect upon contact with the conjunctiva of the eye and skin, does not cause a sensitization effect or an embryotoxic effect. [2]

People who work with the substance often suffer from chronic eczema. When working, it is necessary to protect the respiratory system, eyes and skin from exposure to dust. [3]

Sodium tetraborate, as well as boric acid and soluble borates, are quickly and almost completely absorbed from the gastrointestinal tract. In the blood, boron is evenly distributed between red blood cells and plasma, but quickly passes into the tissues. Found in soft tissues

10% of the dose (mainly in the brain, liver and adipose tissue). The excretion of boron compounds occurs mainly through the gastrointestinal tract. [3]

Hazard classes. Insecticides based on sodium tetraborate belong to class IV of low-hazard disinfestation agents according to GOST 12.1.007. [2]

How to treat

Treatment depends on the severity of symptoms and the cause of inflammation. After the examination, the doctor prescribes a course of symptomatic (elimination of symptoms), pathogenetic (intervention in the mechanism of disease development) and restorative therapy. In accordance with this, the following recommendations can be distinguished:

- Correction of nutrition and lifestyle.

- A nutritious diet, taking multivitamins, giving up bad habits and strict adherence to the drinking regime are the basis of not only treatment, but also the prevention of seizures in the oral cavity.

- Drug treatment.

Given that diabetes is the most common cause, blood sugar levels need to be monitored. This can be done by adjusting your diet, as well as taking medications. A course of multivitamins helps control deficiency conditions and prevent other complications. If seizures in the corners of the mouth were caused by fungi or bacteria, appropriate medications are prescribed: antifungals, antibiotics, etc.

- Maintaining oral hygiene.

This is one of the main conditions that will help not only get rid of symptoms, stop inflammation, but also prevent their re-formation.

- Protection of the red border of the lips.

It is quite sensitive to ultraviolet rays, wind and other irritating factors. Therefore, you need to use hygienic lipsticks and gels that will help reduce dryness and protect the red border from the irritating factor of saliva. In some cases, medications may be recommended to promote healing.

- Lip shape correction.

The main thing about borax with glycerin

In appearance, borax with glycerin has a transparent 5–20% solution with a slight specific odor.

Sodium tetraborate contains:

- the main substance is borax or sodium tetraborate decahydrate (20 g)

- excipient - glycerol or glycerol (80 g).

Borax with glycerin is available in glass bottles and with a nylon and tightly screwed plastic cap, 30 g each. Borax itself acts as an antiseptic, or rather eliminates various infections, and glycerin removes irritation and helps the borax penetrate skin barriers better. Using glycerin, the solution becomes thick.

Causes of sticking in the corners of the mouth

If you lick your lips frequently, the red border becomes dry and this predisposes you to irritation and inflammation. Cracks form in this area and may bleed. Then a secondary infection may occur.

Most often, the cause of inflammation is yeast-like fungi, but bacterial infections, for example, the action of staphylococci and streptococci, cannot be excluded. Sometimes, against the background of fungal inflammation, bacterial inflammation, provoked by staphylococcus, joins.

In some cases, it is impossible to determine the exact cause of inflammation. This is called idiopathic angular cheilitis.

Application of brass and copper powder

Practitioners often use flux that has been stored longer than expected. To solder with brass, the borax must be re-melted. The cooled powder should be placed in a jar with an airtight lid. Neglecting this procedure can ruin the work due to waste accumulated during storage.

At the beginning of soldering, the working area must be heated to a clearly visible red color. Heating should begin first at the edges, and then directly at the soldering site.

Then the heated area should be gradually sprinkled with flux, wait until it spreads in the form of a film along the edges of the part. At this point, the heated brass solder must be dipped into the molten borax so that it is covered with a hot flux film.

As experience shows, the soldering area is red in color, while the borax melt is colored bluish. You cannot keep solder in the flux for a very long time. Oxide residues may form.

Then you should warm up the work area again. The brass will take on an orange glowing appearance. You can proceed directly to soldering. If done correctly, the solder will fill all the gaps.

The soldering area will turn golden. When the process is completed, the hot zone should be sprinkled with borax powder and left to cool. Copper parts in a hot (200 ℃) state can be placed in a mixture containing equal parts acetone and water, or simply in water. It makes sense to immerse the cutters in hot sand.

A correctly made connection has a transparent film with a slight blue tint. There are no solder drops on it. If soldering is performed incorrectly, the seam becomes covered with a black porous crust.

The reason may be overheating of the working area, as a result of which slag is formed, or poor quality of borax-based flux. This is how brass and other copper-containing alloys are soldered.

Story

Borax-based preparations have long been an effective remedy against cockroaches. The following recipes were used:

- take powdered sugar, flour and borax in equal proportions and in dry form, mix. Scatter in places where cockroaches often appear;

- Mix borax, flour and capsicum and also sprinkle in places where cockroaches are observed;

- mix finely ground rosin, powdered sugar and borax, sprinkle for three days where cockroaches appear;

- Dissolve borax in hot water and moisten pieces of bread with this solution. For several days in a row, place bait in places where cockroaches appear and the next day destroy the poisoned cockroaches and bait.

Borax-based baits were also used against rodents - borax, powdered sugar and finely ground rosin were mixed with a plastic spatula. Sprinkle the mixture near the holes formed by rodents.

Copper pipe connection

Copper pipelines are expensive. The investment can be justified with careful installation, which is often carried out by capillary soldering using borax as a flux.

It is worth noting that today, other fluxes are sold that are more convenient to use. One pipe is inserted into the second or fitting so that the gap does not exceed 0.4 mm.

Soldering time is short, 3 minutes. It is important that the parts remain stationary during operation. In order for the borax powder to stick to the surface, the copper is first heated with a torch.

For pipes with a diameter of up to 108 mm, the soldering process is carried out at low temperatures not exceeding 450°. The seam is wide (up to 50 mm), but not very strong. Wide pipes with a diameter greater than 159 mm are soldered at high temperatures. Only professionals can perform the procedure.

In both cases, the solder melt penetrates well into the capillaries of the parts, which contributes to the formation of strong connections. It is recommended to remove any remaining borax.

It must be remembered that soldering is accompanied by the formation of smoke, so you can only work in ventilated areas.

Storage conditions

Slime made from tetraborate should be stored in a cool place . It may be a refrigerator or a balcony, but not a freezer. If the toy freezes and becomes covered with ice, then after defrosting it will no longer be possible to restore the previous structure.

Moisture is also dangerous for slimes. If it gets moldy, you will have to throw it away. To prevent this from happening, store the slime in an airtight container. Otherwise, the toy may dry out and it will become impossible to play with it.

The lifespan of slime from the moment of creation ranges from 2 weeks to 2 months.

How to make borax at home?

The cost of sodium tetraborate in hardware stores and pharmacies varies from 20 to 100 rubles. If we are talking about a one-time use, then the price is cheap, but if a person constantly needs flux or borax for other tasks, it would be more rational to get it at home. In the table below I will describe 3 popular recipes for making the substance with your own hands.

| № | Components | Packing (g) | Preparation |

| 1. | Baking soda | 50 | Pour boric acid into a glass container and add baking soda in small portions. Stir until completely dissolved. Next, we do filtration - we pass the mixture through special paper or a napkin. You should get about 100 grams of sodium tetraborate. |

| Boric acid | 70 | ||

| 2. | Water | 200 ml | Finely chop the laundry soap using a grater. To start, 1 teaspoon is enough. Pour 200 ml of water into a glass container, add boric acid and gradually add crushed laundry soap. Place the mixture in the microwave for a couple of minutes. We filter and get borax. |

| Boric acid | 5 | ||

| Laundry soap | 50 | ||

| 3. | Powdered borax | 20 | This recipe involves obtaining sodium tetraborate in liquid form. Simply mix borax powder with glycerin and leave for a day. |

| Glycerol | 80 |

Although borax itself is not a highly toxic substance, constant exposure to human skin can lead to dermatitis. If a person, due to his profession, periodically interacts with this inorganic compound, I strongly recommend using gloves, safety glasses and a respirator.

What kind of workwear should a welder have?

This concludes the analysis of the concept of what borax is. I hope that the information provided was of value to you. Share in the comments where exactly you encounter sodium tetraborate in practice. Good luck and good health to you!

How can I replace sodium tetraborate?

Depending on the purpose for which you plan to use sodium tetraborate, you can choose a substitute:

- To exterminate cockroaches, you can use regular baking soda instead of borax.

- If tetraborate is used to prepare slime as a thickener, then it can be replaced with starch or Teymurov’s foot ointment, which contains both sodium tetraborate and boric acid.

- Furacilin can be used as an antiseptic for stomatitis or thrush instead of sodium tetraborate.

- To remove mold, instead of a borax solution, you can use a solution of copper sulfate.

Making sodium tetraborate at home is a very entertaining activity that can bring a lot of pleasure to both adults and children. The main thing is not to forget to take precautions and be careful!

3.4/5 — (5 votes)

Stone care

When using borax, you must take precautions: store in a closed container in a dry, dark place, use protective gloves when working and avoid contact with skin and mucous membranes.

Previous article Mineral brookite - properties, deposits and applications Next article Mineral vanadinite - properties, significance of the stone and applications.

Sources

- https://pressadv.ru/samodelkinu/bura-formula.html

- https://stroy-podskazka.ru/pajka/bura/

- https://ArmRinok.ru/obrabotka/bura-v.html

- https://m-strana.ru/articles/bura-formula/

- https://WikiMetall.ru/spravochnik/chto-takoe-bura.html

- https://kamneteka.com/bura-svoystva-znachenie-i-primenenie/

- https://pressadv.ru/stali/bura-tehnicheskaya.html