What is a nylon prosthesis

Removable nylon dentures are soft orthopedic structures made of a pink, gum-colored nylon base with invisible clasps that hold it in the mouth. The fixation is on the adjacent teeth; the hooks wrap around the supports, keeping the prosthesis stationary on the jaw. Artificial crowns are placed on an elastic frame.

A person can take off and put on a nylon prosthesis without assistance. They are used in dentistry as a temporary solution during implantation (during the process of osseointegration) or as a permanent prosthesis according to indications.

Nylon is a polymer that has the quality of flexibility, and under certain conditions, in the patient’s mouth, softness increases. As a denture material, it has come as an alternative to dental acrylic, to which some people are allergic.

Partial nylon prosthesis RUR 40,000. for all!

The price includes: diagnostics, impressions, manufacturing, installation, fitting and 1 year warranty! Complete denture Akrifri 1 jaw - 47,000 rub.!

When is denture repair required?

Cracks

The most common requests for urgent repair of a prosthesis are related to cracks in the structure. Therefore, it makes sense to immediately consult a doctor in order to avoid the worst-case scenario of further developments, when the product splits into several parts. This often happens, for example, with removable plastic dentures.

Chips and breaks

Patients with chips on artificial crowns often turn to dentistry for denture repair. And this is absolutely correct! The sharp edges of broken crowns can injure the oral cavity, so a damaged denture definitely needs urgent repair. You should also contact the clinic if a fragment of the outer layer breaks off from the metal-ceramic crown. Such repairs will not take much time, and the doctor will most likely restore the damaged crown using composite materials. However, in some cases, the artificial crown may even fall out of the base.

Damage to fastenings

Also, fastenings of various types of prostheses are susceptible to breakage: clasps, locks or telescopic fixation elements.

Need for relocation

Relining of the prosthesis is carried out in cases where small gaps or cracks form between the base of the prosthesis and the patient’s gums or teeth, preventing a tight fit. This problem can cause changes in diction, malocclusion and injury to soft tissues, so repair of dentures in dentistry should be carried out as early as possible.

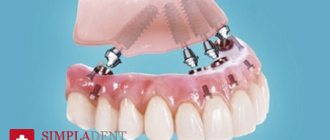

Stages of manufacturing a flexible prosthesis

To create nylon dentures, you must first treat the teeth, perform removal according to indications, and then proceed to the following steps:

- taking impressions of jaws in a clinical setting;

- plaster models are made in the laboratory;

- a wax prototype of the prosthesis is cast, tried on, and finalized;

- a nylon final version is created, matched to the color of the gum. The equipment used is a heat press, in which polymer granules are melted and an individual mold is poured in a liquid state. After hardening, the structure is polished.

Clasps are a continuation of nylon dentures and are therefore completely invisible on the jaw even when smiling and talking.

Indications for installation

Indications for removable nylon dentures can be:

- loss of one or more teeth in a row;

- scattered defect;

- absence of all teeth;

- allergy to metal, acrylic;

- if you do not want to grind the supporting teeth for dentures, for example, clasp ones with locks;

- periodontal disease of 1st and 2nd degrees to keep teeth in place (but 3.4 degrees will already be a contraindication);

- patient refusal or medical contraindications to implantation;

- childhood, if necessary, hide early tooth loss;

- as a temporary solution for implantation with delayed loading.

Sometimes nylon dentures can be installed to treat bruxism, involuntary grinding in the mouth, which damages tooth enamel and increases wear. And also for athletes and people involved in traumatic sports, a flexible design is the best option, better than acrylic, which can easily break in case of injury.

How to repair fixed structures

Fixed orthopedic systems include artificial crowns, bridges, as well as microprostheses: restoration inlays, veneers and lumineers. Any prostheses attached to implants can be included in this category. If, if the integrity or fastening of implant systems is damaged, a complete re-treatment has to be carried out, then crowns and “bridges” can most often be repaired.

Crown restoration

In the event of a chip, the broken fragment is returned to its place and secured using a photopolymer composite. If there is no chipped piece, the doctor will simply restore the shape of the orthopedic product using the same material. Of course, repairing artificial teeth is much cheaper than replacing them completely.

Using a special material, a specialist hides the defect

As for the repair of fixed single dentures, there are two options: with and without removable ones. The problem is that when removing the product there is a risk of further damage to it, especially if we are talking about an all-ceramic model. On the other hand, modern equipment allows de-cementing to be carried out extremely carefully and with minimal risks. However, if the situation allows, repairs are carried out directly in the patient’s oral cavity.

Repair of "bridges"

Restoring bridge structures usually involves restoring artificial teeth. If the base is fractured, the product must be completely replaced, which is also true for cases of destruction of supporting teeth.

Contraindications

What may be a contraindication to a nylon prosthesis in dentistry:

- periodontal diseases (grade 3-4 periodontal disease), loose teeth, their displacement;

- recession;

- the height of the supporting teeth is not enough, the clasps will not be able to securely fasten;

- inflammatory processes of the mucous membrane and gums;

- tooth mobility;

- significant bone atrophy.

It is necessary to have healthy teeth on both sides of the prosthesis as supports for clasp fixation.

Why a prosthesis can be damaged/broken - common reasons

Like any other product, dentures sometimes break and fail, regardless of the model and design features of the device. There are many potential reasons for this problem, and here are the most common ones:

- a defect in the design itself as a result of an error made at the stage of its manufacture,

- incorrect installation of the product in the oral cavity,

- neglect of hygiene rules and lack of proper care of the structure,

- increased chewing load or careless handling of the orthopedic apparatus,

- injuries resulting from blows or falls,

- low quality of the material from which the orthopedic system is made,

- structural changes in supporting teeth - their loosening and destruction, including under the influence of caries or inflammatory processes in the gums.

You can break dentures by biting hard objects.

And here it should be noted that breakages are different and not all of them lead to complete failure of the product. Orthopedic dentistry specialists are engaged not only in the manufacture, but also in the repair of such devices, which often allows saving on complete re-prosthetics.

Varieties

There are:

- mini dentures for 1-2 teeth;

- partial (in the absence of three or more teeth);

- complete (replacing the dentition of the entire jaw).

Many people mistakenly believe that all flexible prostheses are nylon. This is wrong. They are very similar to the touch and in some characteristics. However, they should be considered separately.

Quadrotti prosthesis

A special modern type of prosthesis, which stands somewhere between clasp and nylon. It is more durable than the latter, has a little flexibility, and the fasteners are also not visible, unlike the clasp design, where, perhaps, this is the only drawback. The material of manufacture is monomer-free plastic.

Immediate prosthesis “butterfly”.

This is just a type of nylon prosthesis. It is used in cases where one, or less often, two teeth are missing. Small design, good replacement for a lost dental element. Produced quickly. The supporting teeth are not affected, that is, the doctor does not grind them down, they remain healthy and serve their term.

Rules of care and wearing features

In order for the prosthesis to look aesthetically pleasing throughout the entire period of use, you should adhere to simple rules for caring for it:

- brush your teeth and teeth 2 times a day;

- the toothbrush should have soft bristles and the toothpaste should be non-abrasive;

- After each meal, also clean the product or rinse your mouth with water if it is not possible to remove and thoroughly wash the denture;

- take it to the dentist for professional cleaning twice a year;

- do not store in a dry place;

- periodically use a special solution to disinfect and clean removable dentures.

Removable products and their “weak” points

Cracks and scratches may also appear on the crowns of removable dentures - usually the result of using inappropriate hygiene products, in particular highly abrasive toothpaste and brushes with too stiff bristles. Eating solid foods also leads to similar problems; using teeth for purposes other than their intended purpose, such as opening bottles or cracking nut shells; sudden temperature changes in food and drinks.

Removable dentures are also prone to breakage

Large chips may form on the crowns, and in some cases, artificial teeth even fall out of the base. In other situations, fastening elements fail, cracks and breaks occur in the product itself.

All of the above problems require mandatory consultation with a specialist. If the design is faulty, it should never be worn, otherwise it can lead to disruption of the dental system, destruction of remaining teeth, and the development of inflammatory processes in the gums and periodontal tissues.

Advantages

An undoubted advantage is the aesthetic appearance, better than that of acrylic and clasp structures. And:

- light weight, which is a significant factor for the upper jaw, where a person feels every gram of a foreign body;

- small basis. There is no wide part blocking the sky, like the plate analogue, which is much more comfortable;

- quick addiction is due to the two points above;

- “invisible prosthesis”, invisible to others, a person can laugh and talk without hesitation. Nylon, in this sense, is a good material; it perfectly imitates gums. And since the clasps are a continuation of the base and are of the same color, they are attached directly to the gums behind the supporting tooth, so they are not visible. What is an advantage over metal visible hooks of clasp structures and acrylic ones;

- hypoallergenic. The production does not use toxic monomers that are added to the plastic mass of acrylic prostheses. They are the ones who cause allergies in patients. By the way, other alternatives to prosthetics have appeared for such sensitive people - Acry Free;

- there is no metallic taste in the mouth due to the absence of metal in the composition;

- The next plus will be felt by people who have a small mouth. Opening it wide to install a large prosthesis is not very comfortable. But not in this case. Nylon bends easily and does not require such sacrifices from patients.

Flaws

It cannot be said that all the disadvantages that we describe below apply to mini-prostheses. They are the ones who receive the least number of complaints. But larger designs definitely have the following negative nuances:

- uneven load when chewing and discomfort when chewing food. The base is flexible and when bitten it bends even more, all the pressure goes to one area, which causes pain. Since the load is not distributed over the entire prosthetic bed, the tissues underneath it atrophy;

- rapid atrophy. Under any removable denture this process occurs and the height of the alveolar ridge is lost. You can find figures about 1mm per year. Loss of tissue leads to subsidence of the prosthesis;

- damage to the gums in the area of clamp fixation. Unlike the clasp type and the plate type, where the hooks wrap around the neck of the supporting tooth, nylon dentures have a gingival attachment. Therefore, the load when chewing is transferred not to the tooth, but to the gum, which over time injures it;

- a fairly rapid decline in aesthetics. Nylon scratches, becomes sticky over time, and attracts dirt;

- beyond repair;

- short service life - up to 5 years and at the same time the need for frequent corrections.

Products made from what materials can be repaired?

The possibility of repairing an orthopedic structure largely depends on the material from which it is made. For example, acrylic models, which themselves are quite fragile, can be repaired. In this case, cracks are usually covered with self-hardening resins. As for nylon prosthetic devices, their repair, as a rule, involves eliminating chips and cracks on the crowns. Since the base in such products is quite elastic, it is less susceptible to breakage. On the other hand, due to their increased elasticity, such prostheses quickly stretch and lose their original shape, which reduces the strength of their fixation and requires frequent relining.

Plastic crowns are less strong and durable, but metal-ceramic crowns are considered more reliable, but this also has its own nuances. For example, ceramic cladding tends to chip under intense chewing load. Such defects are restored by applying luminous composite materials. Modern materials (adhesives, adhesives and cement compositions, photopolymers) allow the reconstruction of dentures to be carried out quickly and with high quality, which is also helped by advanced computer programs, specialized equipment and tools.

Expert opinion

Roman Borisovich Alekperov

orthopedic dentist

Experience: 24 years

The choice of flexible prostheses is based mainly on the patient’s desire to receive maximum comfort from wearing an orthopedic structure. Nylon or silicone prostheses do not require long-term adaptation - made from an individual cast, they immediately sit comfortably and allow you to chew food and speak normally. It is important to remember that long-term wearing of flexible prostheses can lead to the development of atrophic processes in bone tissue, since these structures do not have a rigid base. Do not use flexible dentures for more than 6-9 months if you are planning to have implants. If such a situation occurs and the bone is “gone,” it will be necessary to pre-build it or perform basal implantation.

Is it possible to repair a prosthesis yourself at home?

To properly repair a prosthetic device, you need specialized equipment and materials. Therefore, at home it is impossible to return the product to its former appearance and correctly restore its functionality. Moreover, cracks, breaks and splits, even if improperly repaired, can pose serious risks to oral health if the appliance continues to be worn.

Remember that self-repair of the prosthesis can completely damage it, and then you will have to pay for a complete re-prosthesis. Do not try to solve such a problem yourself - it is better to entrust it to experienced professionals.

1According to WHO.

Examples of work “Before” and “After”

Partial restoration of teeth on both jaws

Case: partial absence of teeth on both jaws.

Complete prosthetics of the upper and lower jaws

Case: absence of teeth in the upper jaw (completely), absence of an orthopedic structure in the lower jaw on existing implants (installed in the USA two years earlier) Work: production of a complete removable denture in the upper jaw as a temporary structure until the installation of one-stage implants with subsequent prosthetics.

Installation of plate dentures with complete edentia (April 2012)

Case: complete absence of teeth in the upper and lower jaws, weak fixation of the removable denture in the lower jaw.

Complete absence of teeth in the upper jaw

Case: Completely edentulous upper jaw Work: Complete removable plate denture - acrylic Number of visits: 4 Time: 2 weeks Cost: 25,000 rub.

How to repair removable dentures

The category of removable orthopedic systems includes nylon and acrylic models, clasp structures, prostheses of the new generation Quattro Ti and Acry-Free. The possibility of reconstruction in the event of a breakdown largely depends on the type of damage and its extent. Thus, a full-fledged fracture of the base can rarely be corrected; chips and cracks on crowns and damage to fasteners are more often restored. If the crowns fall out, they are replaced with new ones, which are literally soldered into the appropriate places.

Things will be much more complicated with clasp structures. If a metal arc is damaged, it must be soldered, and to obtain a high-quality result, high precision of work is important. To begin with, the crowns and base are removed, after which the metal fragments are soldered together using a laser.

Not all removable structures can be repaired

Below is a schematic diagram of removable denture repair using an acrylic model as an example:

- all structural elements are thoroughly cleaned, after which they are fastened together using adhesive wax, as well as special fixing devices,

- the specialist applies a special substance to the prosthetic bed for insulation so that the product does not stick to the plaster,

- In order to securely fix all the fragments of the structure in place, a plaster base is created that follows the shape of the patient’s jaw. After this, all fragments of the structure are again separated from each other, and the broken edges are processed with cutters. After processing, the fragments are placed on the lining according to the principle of a puzzle,

- gypsum is coated with a liquid insulator to prevent moisture from entering the new plastic,

- the fragments that are planned to be connected to each other are treated with monomer and fixed to the model,

- Next, the plastic is kneaded and applied to the joints with a slight excess, after which it is subjected to polymerization,

- After the plastic has hardened, the excess is removed, and the surface of the product is ground and polished.

To repair the product, casts are used.

To repair other damage, the use of specialized equipment and tools may be required. A damaged nylon base can be glued using special liquids, but this is not always possible - each case requires individual consideration.