- Materials

- Indications

- Contraindications

- Manufacturing and installation

- Advantages and disadvantages

- Care

- Life time

- Alternative Methods

- Advantages of the ROOTT Clinic

- Prices

- Work examples

- Doctors

- Reviews

- When to use:

any group of teeth - Material:

KHS, gold, silver, palladium - Installation time:

2 to 5 days - Features:

minimal tooth grinding, low price, short service life - Service life:

up to 3 years - Anesthesia:

local

Stamped dental crowns are the oldest in the family of single metal dentures. For a long time, stamping was the only method for manufacturing orthopedic systems. Today, such structures can confidently be called a relic of the past. Structurally, they do not differ from similar prostheses; they are made in the form of a steel cap, 0.2-0.3 mm

, which is fixed to the prepared dental unit.

The production of stamped crowns does not require complex technology. Dentures are created manually, from cylindrical metal caps - factory blanks, sleeves. The dental laboratory has steel sockets of different diameters and thicknesses. The technician selects a blank suitable in diameter and begins stamping the crown. Typically, prosthetic structures are gray or golden in color (depending on the material). At the request of the patient, the prosthesis is coated with gold, titanium nitrite, and lined with plastic or ceramic mass for better aesthetics.

What materials are used

The material of stamped crowns must meet certain requirements - sufficient strength, safety for the body, resistance to oxidation, corrosion, ease of processing, low weight. Various metals and alloys are used:

- iron-based (stainless steel, chromium-nickel alloys);

- based on gold;

- based on silver and palladium.

There are several types of stamped structures:

- all-metal

- have a metallic color and shine; - combined

stamped crowns - the front metal wall of the structure is cut out and replaced with a plastic surface. Used for prosthetics of incisors, premolars; - with sputtering

- covering the crown with a thin layer of gold or titanium nitrite, which provides the prosthesis with a golden surface; - with lining

- a plastic or ceramic mass is applied to the finished cap, matched to the tone of the natural enamel.

The stamped crown with veneer is similar in appearance to natural teeth. If the supragingival part of 2-3 adjacent units is destroyed, a single structure is installed on each of them, without soldering into a bridge. The solder area is more susceptible to breakage under chewing stress. In addition, if 1 cap is damaged or deformed, the entire system will have to be removed.

Indications

Typically, stamped crowns are placed when the natural parts of the tooth can no longer be restored with fillings or inlays. This usually happens when more than 1/3 of the tissue is removed along with caries.

Except in cases of caries or impact trauma, stamped crowns can be placed as bridge abutments. This allows you to avoid grinding down excessively healthy teeth, or when it is impossible to install a cast structure.

Sometimes such crowns can even be placed on children’s baby teeth to correct their bite.

Contraindications

Relative

the procedure can be carried out with extreme caution

- Bite defects;

- increased abrasion of the enamel of the antagonist tooth;

- gum pathologies (atrophic, inflammatory);

- pregnancy;

- allergy to anesthetics;

- acute infections;

- mental disorders;

- exacerbation of a chronic disease.

Absolute

the procedure is strictly prohibited

- Severe periodontitis with tooth mobility grade III-IV;

- malignant processes of the oral cavity;

- allergy to prosthesis material;

- decompensated diabetes mellitus.

How long does adaptation take?

How long does it take to get used to stamped crowns? As a rule, adaptation takes very little time - a day or two. It all depends on how well the structure is made and how long the patient walked with a damaged tooth. Since the product follows the anatomical shape, there is no particular discomfort when getting used to it.

Complex on 4 OSSTEM implants with delayed loading - from RUB 170,000.

Complex implantation Osstem (South Korea) with delayed loading after 4-6 months.

Guarantee for the doctor’s work - unlimited Call now or order a call

Opening hours: 24 hours a day - seven days a week

Manufacturing and installation

The technology for making stamped dentures is simple; all you need are consumables, tools and the professionalism of a dental technician. The prosthetic procedure includes a clinical and laboratory stage.

Clinical

- Diagnostics

- examination by a doctor, x-ray diagnostics, drawing up a treatment plan, choosing the type of prosthesis. - Preparation

- preparation of the tooth for a stamped crown to the thickness of the structure (

0.25-0.3 mm

), taking into account safety zones, determination of central occlusion. If the tooth is rotated around its axis, the most protruding areas are ground off to correct its position in the row. - Impressions

– taking impressions of both jaws, installing a provisional (temporary) crown made of polymerizing plastic. - Installation

– control fitting, fitting of the prosthesis, fixation with dental cement.

Laboratory

The laboratory stage of manufacturing a stamped crown includes:

- Plaster modeling

– a plaster blank (model) is created based on the impression.

It is modified - a small depression is formed in the gingival area (about 0.5 mm

). The plaster model is trimmed, given more accurate contours, preserving all anatomical details, and checked in an occluder. The anatomical features of the tooth surface are reproduced using modeling wax. - Making a metal stamp

- using a plaster stamp, a metal stamp is made by casting. For each dental unit, 2 stamps are made - for preliminary and final stamping of the orthopedic system. - Pre-stamping of crowns

- the technician selects a sleeve according to the diameter of the dental crown so that it fits onto the metal stamp with some effort. If there is no sleeve of a suitable size, then use a workpiece of the closest possible diameter, pulling it through a special apparatus. The sleeve is fired, cooled, placed on the first stamp, and tapped with a hammer to give it a preliminary anatomical shape. The stamp is driven into the sleeve until the imprint of the chewing surface or cutting edge appears. The preliminary crown is removed by melting the stamp, fired, and cooled. - Final stamping

- the preliminary crown is placed on the second stamp and tapped with a hammer to obtain the correct anatomical shape. The workpiece is placed in the apparatus and subjected to pressure of 3-5 tons. They tap it again with a hammer, cut it to the level of the gums, and send it to the orthopedist for fitting to the patient. - Finishing

– after fitting, the workpiece is again transferred to the laboratory, bleached in an acid solution, ground and polished to make the surface smooth and shiny. At the request of the patient, the prosthesis is covered with ceramic lining or spraying. The finished prosthesis is handed over to the orthopedic dentist.

If it is impossible to process a solid sleeve on a model, soldering technology is used. To do this, the cap sleeve is cut into 2 or 3 parts, each part is modeled with a hammer on a stamp, then all the elements are connected into a single structure by soldering. The tooth for a stamped crown is prepared minimally, since the thickness of the walls of the prosthesis does not exceed 0.2-0.3 mm

.

Errors

- If, when installing a crown, the gingival edge turns pale, then it must be shortened with scissors and a bur, since the design puts too much pressure on the tissue

- If the prosthesis is not put on and it is clear that the diameter of the stump is larger than it should be, then selective preparation can be carried out by removing the interfering areas of the tooth

- If the prosthesis does not fit on due to problems inside the stamping itself or is loose, then it is sent to the laboratory for alteration

- If the structure is too short and does not fit into the gingival sulcus, then you need to start by taking the impression again and repeat all the laboratory steps

Advantages and disadvantages

Advantages

- Manufacturing a stamped metal crown takes 1-2 days;

- can be installed on “living teeth”;

- minimal trimming of hard tissues;

- low price.

Flaws

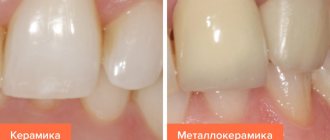

- Low aesthetics even for lined structures;

- insufficient adherence to dental tissues, formation of retention zones (places where food accumulates);

- risk of allergies, galvanism;

- combined structures are subject to delamination of materials, are fragile, and are not suitable as a support for a bridge or orthodontic system;

- plastic stamped crowns absorb foreign odors, food coloring, quickly lose color, crack, chip;

- short service life - 2-3 years;

- the appearance of a bluish stripe around the prosthesis due to metal oxidation (gray neck);

- quick erasing, changing the shape of the chewing surface;

- do not restore the exact anatomical shape of the tooth.

The advantages of stamped crowns are few. There are 2 main advantages: price and ease of manufacture. The designs have significantly more disadvantages. Stamping does not make it possible to produce an anatomically accurate orthopedic system, which is why the product does not fit tightly enough. There remains a gap between the gum and the metal, where bacterial plaque and food debris begin to accumulate. This leads to inflammation of the gums and progression of caries.

Caring for installed stamped crowns

Since in the process of using such dentures, sooner or later the marginal fit changes and a gap is formed between the neck of the tooth, gum and crown, special care measures are required for them. Among the hygienic rules of care are the following:

- Brushing your teeth – at least 2 times a day. The use of a brush with medium-hard bristles is mandatory. The paste is selected with the appropriate mineral composition.

- Be sure to rinse your mouth after eating.

- Use dental floss to clean the space between your teeth.

- No later than 3 months after the installation of the prostheses, visit the doctor who installed them. Make such visits once a quarter a rule, until the very end of the service life. This way you can notice negative changes under the crown in time: the beginning of the carious process, tartar deposits, inflammation. And take treatment measures before the process goes too far and the crown has to be removed.

Alternative Methods

Ceramic-composite metal-free, lightweight crowns with high light transmittance

Zirconium Durable crowns with high aesthetics, suitable for anterior and posterior teeth

Cast Durable and durable one-piece crowns made of metal alloys with the possibility of veneering

Article Expert

Shirokov Ivan Yurievich Dentist-orthopedist, doctor of the highest category

Work experience: more than 17 years

Price

Prices for stamped dentures vary depending on the regional location of the clinic and the presence/absence of a sprayed layer

A wide selection of modern materials is gradually replacing the installation of stamped crowns from the list of services of some clinics.

But the presence of an interested segment of consumers still hinders the final refusal to use this material in prosthetics.

Prices for stamped dentures differ depending on the regional location of the clinic and the presence/absence of a sprayed layer.

The cost of a regular crown is 1,500 rubles. You will have to pay a little more for a product with spraying (1,700 rubles). In the case of making a crown with plastic lining, the price will increase to 2000 rubles.

Prices

Free online consultation with a dentist

| Service | Price |

| Installation of a metal-ceramic crown (Germany Ivoclar, cobalt-chrome) | from 15,000 rub. |

| Installation of a metal-ceramic crown based on a bio-alloy - gold (Ivoclar Germany + cost of material according to the certificate) | from 25,000 rub. |

Consultation and diagnostics are free!

All prices Promotions

Sign up for a consultation

three ROOTT specialists + diagnostics as a gift

Dental laboratory

- Own laboratory

The FDC clinic has its own dental laboratory, equipped with the latest technology, so even the most labor-intensive orthopedic work is performed in the shortest possible time.

- Laboratory in France

Exclusive work, if necessary, can also be performed in the most prestigious dental laboratory in France, Bourbon Atelierd' Art Dentaire (Nice)

Does the patient feel pain during treatment?

Tooth grinding takes place under anesthesia, so there is no pain. But when the anesthesia stops working, pain may be felt both in the tooth and in the gum.

Causes of pain:

- when too much cover is removed;

- when the gums are pulled back (a special thread is used), the tooth may hurt for a couple of days;

- If pain is detected some time after the treatment procedure, an inflammatory process may begin in the tooth.

Adequate alternatives to “stamping”

The best alternatives to a stamped crown are modern cast (solid) and milled ones. What is the difference? The differences between stamped and cast are that they have different manufacturing technologies. Cast, as the name suggests, is made by casting. This allows the use of stronger and more durable metal alloys (for example, with cobalt). Cast dentures are precise - they fit better to the support and to the gums, do not wear down over time, and last about 10 years. They can also be coated with a ceramic veneer to enhance aesthetics.

“The doctor dissuaded me from having a stamped crown because it’s a thing of the past. Although it is cheap, it is from the category of “the miser pays twice.” It’s better to immediately make normal metal ceramics, which will last a long time and pay for itself. Somehow I don’t want to go for a new prosthesis every 2-3 years and finish off the tooth with new drillings.”

Ruslan, review from the website stomatology.rf

Another type of dentures is milled. They are modeled in a computer program and manufactured using a computer-controlled milling machine. This ensures the highest precision - the prosthesis fits onto the support without the smallest gaps, which eliminates the risk of microbial penetration. Titanium, aluminum and zirconium dioxides are suitable for milling - the latter are metal-free ceramics and last 15-25 years.

User Questions

QUESTION Tell me, I have a gray crown on a molar that seems to be stamped. I noticed that the gum area around me was very red. Does this mean it’s time to change the crown or what? Sergey Anatolyevich

ANSWER Hello, Sergey Anatolyevich. Here you need to look at the situation - it is advisable to go to an orthopedist and get an x-ray. It is possible that food gets stuck under the gum, which is why it becomes inflamed. It is also possible that you have an allergy to metal. Perhaps some diseases have appeared under the roots, or cement has dissolved under the crown - and microbes penetrate into the resulting niche. After diagnosis, the dentist will make a verdict - whether the gum can be cured without removing the crown or not.

1Haug S. Correct modeling, 2006.

Author: Sambuev B. S. (Thank you for your help in writing the article and the information provided)

How does turning happen?

At the very beginning of the procedure, the patient is given anesthesia. If work with vital teeth is meant, anesthesia is not used, except in cases where it is necessary to move the gums back using a special thread.

It is best to take an x-ray before the procedure. With its help, the dentist will see all the structural features of the dental organs and possible deviations.

It is also important to take into account the anatomical features of the patient’s teeth and the response of soft tissues to the preparation procedure.